Primary solution

Impact-Driven Approach to Sustainability module

The Impact-Driven Approach to Sustainability (IDA) module assists flower and ornamental producers with the digital registration and analysis of their input consumption data and other farm metrics. It is a standalone standard for producers who do not have another form of GLOBALG.A.P. certification.

Supporting impact-driven farming

What is the Impact-Driven Approach to Sustainability module?

The Impact-Driven Approach to Sustainability (IDA) module facilitates the digital registration of input consumption data and other farm metrics, as well as the creation of anonymized comparison reports of peer producers with similar production conditions. Connected to an established farm management software (FMS), the IDA module enables producers to transform information into records that can track progress, guide optimization efforts, and demonstrate sustainability credentials.

IDA module at a glance

Tracks farm-level data

and identifies areas for improvement

Works with a farm management software

that is GLOBALG.A.P. approved and chosen by the producer

Results in a letter of conformance

to demonstrate the implementation of impact-driven practices

Provides anonymized comparison

reports of peer producers from aggregated data, supporting performance insights

Supports flower and ornamental producers

with metric-based farm management

Offers a standalone solution

which does not require an existing GLOBALG.A.P. certificate

Tracks farm-level data

and identifies areas for improvement

Provides anonymized comparison

reports of peer producers from aggregated data, supporting performance insights

Works with a farm management software

that is GLOBALG.A.P. approved and chosen by the producer

Supports flower and ornamental producers

with metric-based farm management

Results in a letter of conformance

to demonstrate the implementation of impact-driven practices

Offers a standalone solution

which does not require an existing GLOBALG.A.P. certificate

Who should use the IDA module?

The IDA module is applicable to flower and ornamental production processes only.

It is intended for producers who are not yet registered in the GLOBALG.A.P. certification system for another solution. For producers who already hold certification to Integrated Farm Assurance (IFA) for flowers and ornamentals), the IDA add-on offers the same benefits but in a format which can be combined with the IFA audit.

The IDA module is available for producers of all sizes, from smallholders to large groups, and producers can get audited in any country where a GLOBALG.A.P. approved certification body (CB) conducts audits.

Farm management software and the IDA module

Farm management software (FMS) is becoming increasingly prevalent as digitalization spreads within the farming sector. It is used to manage farm operations and production processes, and now also to send the relevant data to the GLOBALG.A.P. IT systems.

Producers wishing to implement the IDA module must use a GLOBALG.A.P. approved FMS provider to ensure compatibility with the GLOBALG.A.P. IT systems.

Which data is collected?

The IDA module applies to farm metrics which many producers already collect, via a FMS or other methods. This information can be used to improve farm processes by equipping producers with information that supports decision making and drives continuous improvement.

For flowers and ornamentals, the relevant data is related to:

Plant protection products

Fertilizer application (e.g., nitrogen, phosphorus, or potassium contents)

Water use

Energy efficiency

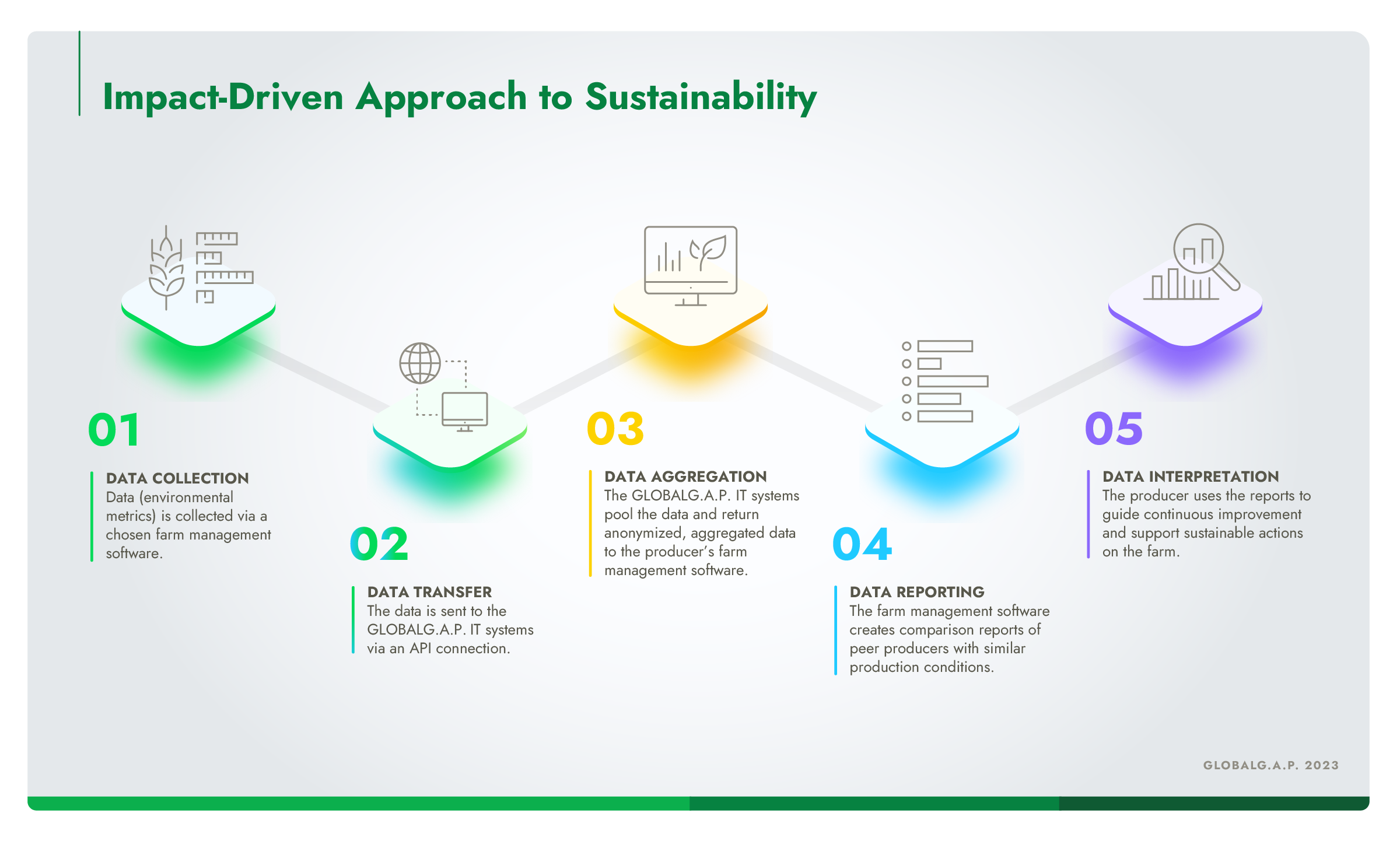

How the IDA module works

Data collection

Each month, producers share their input consumption data via a compatible FMS. This record-keeping procedure is audited annually at farm level by a CB.Data transfer

The data collected in step 1 is sent to the GLOBALG.A.P. IT systems via an API connection.Data aggregation

The GLOBALG.A.P. IT systems pool the data and return anonymized, aggregated data to the producer’s FMS (all data that the FMS shares with GLOBALG.A.P. is treated confidentially).Data reporting

The FMS creates historical trend graphs and anonymized comparison reports of peer producers (producers in the same region, producing the same crop under the same conditions). These reports are returned to the producers.Data interpretation

Producers use the reports to inform decision-making and improve their farm’s efficiency and their environmental credentials.

Discover how the IDA module helps you address sector challenges.

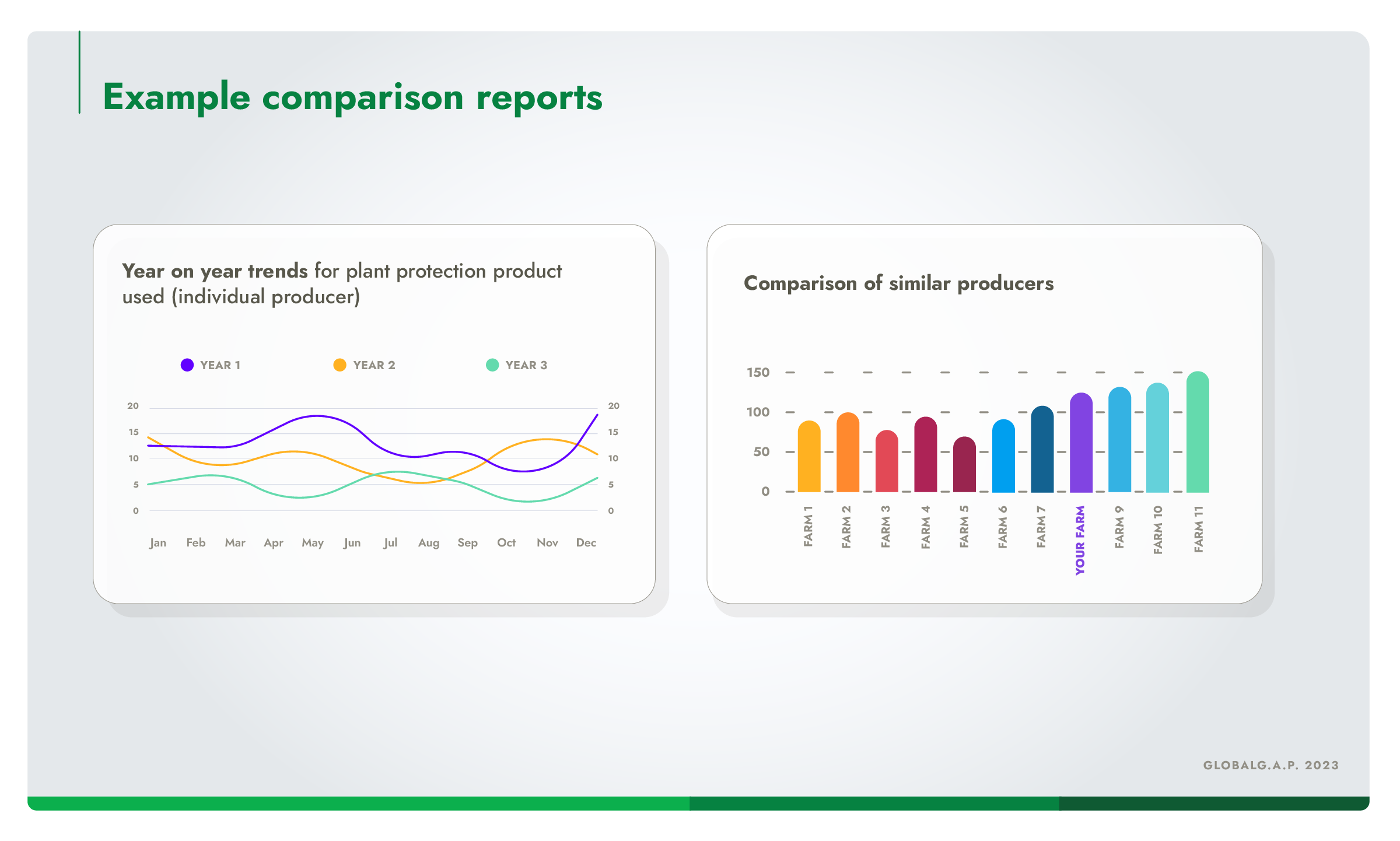

What do comparison reports of peer producers look like?

The FMS will provide producers with comparison reports which have been created from the aggregated and anonymized data from similar producers as shared with GLOBALG.A.P. . The design of these may vary since they are created by the chosen FMS, but the examples below offer an idea of how they display data.

How does the IDA module audit work?

The annual IDA module audit confirms that the producer is recording and submitting relevant and accurate data via the FMS.

After sharing data for a minimum of six consecutive months, producers can be audited against the IDA module by a GLOBALG.A.P. approved CB of their choice.

IDA compliance is audited annually by an accredited and independent third-party CBs.

Producers can choose from any GLOBALG.A.P. approved CB/VB active in the relevant country.

A successful CB/VB audit results in a letter of conformance valid for one year which may be used to meet buyer requirements.

The module is composed of principles and criteria (P&Cs). P&Cs are graded in two levels: Major Must and Recommendation.

Principles

Fundamentals that set the foundation of a GLOBALG.A.P. requirement

Written in statement form

Describe the outcome to be achieved in the corresponding criteria

Criteria

Methods that producers can use to demonstrate a principle to be true

Compliance can be demonstrated in different ways, e.g., data, record of procedure

Evidence must demonstrate that the outcome is achieved

Read more about the audit process and module requirements.

How is conformance status verified?

Every producer registered in the GLOBALG.A.P. certification system is assigned a 13-digit GLOBALG.A.P. identification number (e.g., a GLOBALG.A.P. Number (GGN)). This number allows real-time verification of conformance status in the GLOBALG.A.P. IT platform, upholding our rigorous transparency requirements throughout the supply chain.

In order to maintain a valid letter of conformance, the producer must continue sharing data for all relevant metrics on a monthly basis. If the data is not shared with GLOBALG.A.P. by the 25th of the following month, the producer receives a warning notification from their CB. After the third warning notification, the product is suspended until the gap in the data is closed. This process is handled via your chosen CB.

Producers can control data access and privacy rights for audit reports, and the reports are not shared publicly or with third parties.

Latest news

30 April 2025

Understanding certification integrity in the GLOBALG.A.P. system

What is the GLOBALG.A.P. Integrity Program and how does it contribute to the trustworthiness of GLOBALG.A.P. standards and their worldwide implementation?

29 April 2025

New Zealand GAP scheme benchmarked equivalent to IFA version 6 Smart for fruit and vegetables

New Zealand GAP - GLOBAL v.7 has completed the GLOBALG.A.P. benchmarking process and been confirmed as benchmarked equivalent to GLOBALG.A.P. IFA v6 Smart for fruit and vegetables.

Learn from valuable insights and strengthen your environmental credentials

Why choose the Impact-Driven Approach to Sustainability module?

The Impact-Driven Approach to Sustainability (IDA) module supports producers on their responsible farming journey by turning environmental metrics into practical information that can drive continuous improvement. The resulting letter of conformance from an IDA audit can provide evidence of sustainability efforts and is recognized by the Floriculture Sustainability Initiative (FSI)’s “Basket of Standards”. The IDA module is a standalone primary solution, representing an option for producers without existing certification.

Which industry challenges does the IDA module address?

The floriculture sector depends on a variety of resources, both natural and synthetic, for their production.

With global climate goals in mind, there is growing pressure on growers to minimize their consumption of inputs such as plant protection products, fertilizers, water, and energy.

To demonstrate commitment to more sustainable farm-level practices, producers need to show proof of their continuous, measurable efforts to optimize environmental metrics.

Data records enable producers to observe trends, evaluate performance, and correlate productivity and environmental impact.

The IDA module provides further insights for continuous improvement via historical trend graphs for the sector, for the individual producer, and anonymous peer comparison reports.

Practical information formed of aggregated farm data can equip producers with the knowledge they need to measure themselves and adapt where possible.

Follow our five steps to conformance to get started today.

What are the benefits for producers?

Choose a solution recognized by the Floriculture Sustainability Initiative’s (FSI) Basket of Standards (Environmental basket).

Track input consumption and other environmental metrics to increase awareness of your long-term farm performance.

Gain insights via historical trend graphs and comparison reports of peer producers, which support decision-making and enable you to optimize production processes over time.

Work to minimize your input consumption levels which may reduce the financial burden and strengthen your position in the market.

Rest assured that your individual and identifiable data is not shared with other parties and your efforts are not scored or ranked publicly against other producers.

Benefit from an environmental record-keeping system via a standalone module – no prior certification is required.

Freely choose your farm management software (from a list of approved providers) and certification body (CB) in the open market.

Prepare for the future of metric-based certification schemes and footprint calculations with digital processes.

What are the benefits for supply chain stakeholders?

Ensure producers have performance data in digital form and can share it with the supply chain, if needed.

Enable comparisons between peer producers to incentivize performance improvements that level up the sector as a whole.

Benefit from transparency through real-time validation of conformance status via GLOBALG.A.P. IT systems.

Contribute to global environmental goals by supporting a network of producers who are committed to continuous improvement.

Choose a solution recognized by the Floriculture Sustainability Initiative’s (FSI) Basket of Standards (Environmental basket).

You may also be interested in...

Integrated Farm Assurance for flowers and ornamentals

IFA is a global standard that aims to promote safer and more responsible farming practices in flower and ornamentals production.

Integrated Farm Assurance for plant propagation material

IFA is a global standard that aims to promote safer and more responsible farming practices in plant propagation material production.

Impact-Driven Approach to Sustainability add-on

The IDA add-on aims to promote more responsible farming practices through the collection and analysis of input consumption data and other farm metrics.

GLOBALG.A.P. capacity building

Need assistance with the implementation process? Our capacity-building program offers a range of options for training, consultation, and more!

Your guide to implementation

How to prepare for an Impact-Driven Approach to Sustainability module audit

Learn more about the key documents and fee structure of the Impact-Driven Approach to Sustainability (IDA) module. Follow our five steps to the IDA module for an overview of the audit process, and find a GLOBALG.A.P. approved certification body (CB) in your area to get started.

Implementation and CB audit process

How does the audit process work?

After sharing data for a minimum of six consecutive months via an approved farm management software (FMS), producers can be audited against the IDA module by a GLOBALG.A.P. approved CB of their choice.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a letter of conformance valid for one year. In order to maintain a valid letter of conformance, the producer must continue sharing data for all relevant metrics on a monthly basis.

The CB is responsible for uploading the audit report and maintaining the accuracy of producer data in the GLOBALG.A.P. IT systems.

Producers will be audited annually by a CB as part of the renewal process.

Which documents are required?

GLOBALG.A.P. general regulations specifications: Rules that define how the audit process works, from the scope of the module to the audit requirements.

Principles and criteria (P&Cs): Principles are the fundamental requirements for each standard or add-on. They describe the outcome to achieve and are accompanied by corresponding criteria that detail the various ways in which a producer can demonstrate compliance.

Checklist: The full list of P&Cs as used by CB auditors, enabling producers to conduct a self-assessment in preparation for the CB audit.

Which version of the IDA module is currently valid?

The IDA module is currently valid for flowers and ornamentals in v1.1.

It was published on 16 December 2024 and replaced v1 on 1 April 2025.

The FAQ contains more information on documents, the renewal process, and more.

What are the IDA module requirements?

P&Cs are graded in two levels: Major Must and Recommendation.

To pass a CB audit, producers must comply with 100% of the Major Musts:

Corrective actions must be proposed for all non-compliances and submitted to the CB within the specified period.

Non-compliances must then be verified as corrected and compliant by the CB before a letter of conformance can be issued.

In order to maintain a valid letter of conformance, the producer must continue sharing data for all relevant metrics on a monthly basis.

If the data is not shared with GLOBALG.A.P. by the 25th of the following month, the producer receives a warning notification from their CB. After the third warning notification, the product is suspended until the gap in the data is closed.

How much does an IDA module audit cost?

Each farm is unique, and the total audit costs depend on a combination of factors such as farm size, number of sites, location, necessary preparation measures (such as establishing new procedures), and more. The IDA module contains four cost elements:

FMS license fee: Determined and invoiced by the chosen software provider required for the IDA module

Implementation costs: Incurred by the producer to prepare for the CB audit

CB service fees: Determined and invoiced by the CB to cover audit time and travel costs

GLOBALG.A.P. fee: Calculated based on farm size and invoiced by the CB

The GLOBALG.A.P. fee table contains full information on the fee structure for each standard and add-on.

Five steps to the IDA module

Search the list of GLOBALG.A.P. approved FMS providers. Contact the provider of your choice and start digitally sharing your input consumption data. Note that the GLOBALG.A.P. fee table does not contain or include FMS license fees.

You will need the GLOBALG.A.P. general regulations specifications, the IDA module P&Cs, and the checklist. All of the required documents are available online, for free, and in multiple languages. They are linked below and can also be found in the GLOBALG.A.P. document center. Use the documents to guide the implementation of the module requirements, and then conduct a self-assessment using the checklist.

After sharing data for a minimum of six consecutive months, you can plan your CB audit. Search the list of GLOBALG.A.P. approved CBs by region, country, scope, and status. Contact the CB of your choice and request an audit. Note that the GLOBALG.A.P. fee table does not cover CB service fees such as audit time or travel costs to your site.

The CB will conduct the audit to confirm the completeness and reliability of the data and upload the results to the GLOBALG.A.P. IT platform. Any non-compliances which are detected during the CB audit must be corrected within the specified period and verified by the CB before a letter of conformance can be issued. All data belongs to the producer and is used to generate comparison reports.

Once all requirements are met and verified by the CB, they will issue your IDA module letter of conformance. Your status is then publicly visible in the GLOBALG.A.P. IT systems for transparency in the market. In order to maintain a valid letter of conformance, the producer must continue sharing data for all relevant metrics on a monthly basis. If the data is not shared, the producer receives a warning notification from their CB. After the third warning notification, the product is suspended until the gap in the data is closed.

Key documents

The three most relevant documents are linked below. Click ‘view more’ to see further related documents. Remember to always check with your CB that you have all necessary documents prior to audit.

IDA module

Principles and criteria (P&Cs) (CPCCs)

V1.1

English | Last updated: 05/05/2025

Principles and criteria (P&Cs) (CPCCs)

V1.1

English | Last updated: 05/05/2025

Principles and criteria are a complete list of the requirements for a given standard or add-on. The foundational requirements each detail an outcome that must be achieved, and the corresponding ways in which compliance can be demonstrated.

IDA module

Checklists

V1.1

English | Last updated: 29/04/2025

xlsx

Checklists

V1.1

English | Last updated: 29/04/2025

xlsx

Checklists are documents containing standard/add-on principles and criteria which are used during the audit/assessment to check whether compliance is achieved. They may also be used to conduct self-assessments.

GLOBALG.A.P. approved CBs

The list of GLOBALG.A.P. approved CBs can be filtered by region, country, scope, and status. Click a CB to find more information and contact details.

If you do not filter your search, or filter only according to region and/or country, your search results will also show CBs that offer certification against benchmarked schemes, but which may not have approval for any GLOBALG.A.P. standards and add-ons.

Upcoming events

07 May - 08 May

2025

The Western Food Safety Conference 2025

Location: Salinas, California

Event type: All events

Event format: On-site

14 May - 15 May

2025

GLOBALG.A.P. at Sustainability osapiens Summit 2025 (SoS.25)

Location: Mannheim, Germany

Event type: Keynote speaker

Event format: On-site

GLOBALG.A.P. approved farm management software providers

Filter the list below to find compatible FMS providers approved for the Impact-Driven Approach to Sustainability (IDA).

A brief history of the IDA module

The first IDA module is published in 2020 for the floriculture sector only. It offers a metrics-based and outcome-oriented solution in response to market demand for environmental registration solutions in the Floriculture Sustainability Initiative’s “Basket of standards”.

The IDA module requires time for producers to begin entering data for a minimum of six months before the CB audit. The first producer is audited in April 2021 and by the end of the year, four producers undergo an IDA audit in two countries.

By the end of 2023, 46 producers in five countries are audited to the IDA module.

Version 1.1 of the IDA module was published on 16 December 2024.

FAQ

The IDA module is for flower and ornamental farms without existing GLOBALG.A.P. certification.

It is accessible for all farm sizes and types.

Each farm is unique, and the total costs depend on a combination of factors such as size, location, existing policies and processes, etc. The invoice from your certification body (CB) will include CB service fees to cover expenditures (determined by the CB) and the GLOBALG.A.P. system participation fee (size-based, determined based on hectares/metric tons of annual production).

In addition, there are fees for your farm management software, determined and invoiced by the software provider.

The producer maintains ownership of their shared data. All data that the producer shares with GLOBALG.A.P. via the farm management software is treated confidentially and only shared with other producers in aggregated and anonymized form – e.g., via historical trend graphs, progress reports, and anonymized comparison reports of peer producers.

Producers are not ranked publicly on their performance and personally identifiable data is not shared with other parties.

In order to maintain a valid letter of conformance, the producer must continue sharing data for all relevant metrics on a monthly basis. If the data is not shared with GLOBALG.A.P. by the 25th of the following month, the producer receives a warning notification from their CB. After the third warning notification, the product is suspended until the gap in the data is closed. This process is handled via your chosen CB.

No, the suspension will be lifted by your certification body (CB) as soon as the gap in the data is closed.

IDA module v1.1 documents are currently available in:

Dutch

English

Spanish

German

All documents are located in the GLOBALG.A.P. document center. More languages are added based on demand – please contact us with requests.

The IDA module is intended for flower and ornamental producers who do not have existing GLOBALG.A.P. certification. For producers who already have GLOBALG.A.P. certification to Integrated Farm Assurance (IFA) for flowers and ornamentals, we offer an IDA add-on which can be audited together with IFA.

IDA module compliance is audited annually. The certification body (CB) audit must take place within the validity period of the current letter of conformance in order for your production processes to retain the conformance status. Contact your CB to request an audit.

GLOBALG.A.P. trademarks may be used in a strictly B2B context and must be accompanied by a GLOBALG.A.P. identification number (e.g., the producer’s GLOBALG.A.P. Number (GGN)) or a QR code to a producer’s conformance status in the GLOBALG.A.P. IT systems. The trademarks should never appear to consumers, for example on product packaging.

Download the GLOBALG.A.P. trademarks use: policy and guidelines and GLOBALG.A.P. trademarks use: FAQ documents for comprehensive information on rules and use cases.

If your farm management software provider is interested in becoming GLOBALG.A.P. approved, they can contact customer_support@globalgap.org to begin the process.

If your farm management software provider does not want to collaborate with GLOBALG.A.P., you will need to switch to an approved farm management software in order to be audited against the IDA module.

It is possible – you just need to inform your certification body.

Technical questions can be addressed to standard_support@globalgap.org. Your query will be forwarded to the relevant technical expert.

The GLOBALG.A.P. Academy offers public training courses on our portfolio of smart farm assurance solutions, while our worldwide network of Registered Trainers offer authorized trainings and other services. See the GLOBALG.A.P. Academy course catalog or find a Registered Trainer for more information.

View our CB page to learn more about how to become a GLOBALG.A.P. approved CB or extend your auditing scope.

To learn about becoming a GLOBALG.A.P. approved VB, please see our eligibility requirements.

The CB/VB auditor requirements for the IDA module are detailed in the GLOBALG.A.P. general regulations specifications for the IDA module.

Contact us

For technical/interpretation questions, please contact us at standard_support@globalgap.org.

For questions about the audit process or GLOBALG.A.P. IT platform, please contact us at customer_support@globalgap.org.