Core solution

Produce Handling Assurance

Produce Handling Assurance (PHA) provides food safety and traceability certification of postharvest activities such as the cooling, packing, handling, and storage of crops for human consumption. It is recognized by the Global Food Safety Initiative (GFSI) and supports compliance with the Food Safety Modernization Act (FSMA).

Demonstrate responsible postharvest practices

What is Produce Handling Assurance?

Produce Handling Assurance (PHA) addresses food safety and traceability in postharvest preprocessing activities for crops under the categories of cooling, packing, repacking, and storage/distribution. It can be combined with Integrated Farm Assurance (IFA) or the Harmonized Produce Safety Standard (HPSS) to provide a complete certification option for producers with on-farm packing or other postharvest activities. The standard goes beyond existing postharvest handling requirements in IFA and HPSS to ensure that responsible processes are maintained after the primary production stage. It can also be used as a standalone certification option for independent postharvest facilities. PHA is benchmarked to the Global Food Safety Initiative (GFSI v2020.1) and is accepted by buyers globally.

PHA at a glance

Covers preprocessing

production stages after the point of harvest, including cooling, packing, repacking, handling, and storage

Recognized by GFSI

with successful benchmarking against GFSI v2020.1 for Scope BIII – Pre-Process Handling of Plant Products

Available to all qualified

preprocessing operations, from enclosed and open shed packhouses to cold storage (fully enclosed operations in the European Union excluded)

Audited in combination

with IFA (for fruit and vegetables/combinable crops/hops) or HPSS

Incorporates FSMA

requirements from both the PSR and the PCHF Rule, reducing duplication for producers

Audit reports and certificates

can be provided to importers, retailers, and other value chain stakeholders as evidence of an operation’s efforts toward FSMA implementation

Covers preprocessing

production stages after the point of harvest, including cooling, packing, repacking, handling, and storage

Audited in combination

with IFA (for fruit and vegetables/combinable crops/hops) or HPSS

Recognized by GFSI

with successful benchmarking against GFSI v2020.1 for Scope BIII – Pre-Process Handling of Plant Products

Incorporates FSMA

requirements from both the PSR and the PCHF Rule, reducing duplication for producers

Available to all qualified

preprocessing operations, from enclosed and open shed packhouses to cold storage (fully enclosed operations in the European Union excluded)

Audit reports and certificates

can be provided to importers, retailers, and other value chain stakeholders as evidence of an operation’s efforts toward FSMA implementation

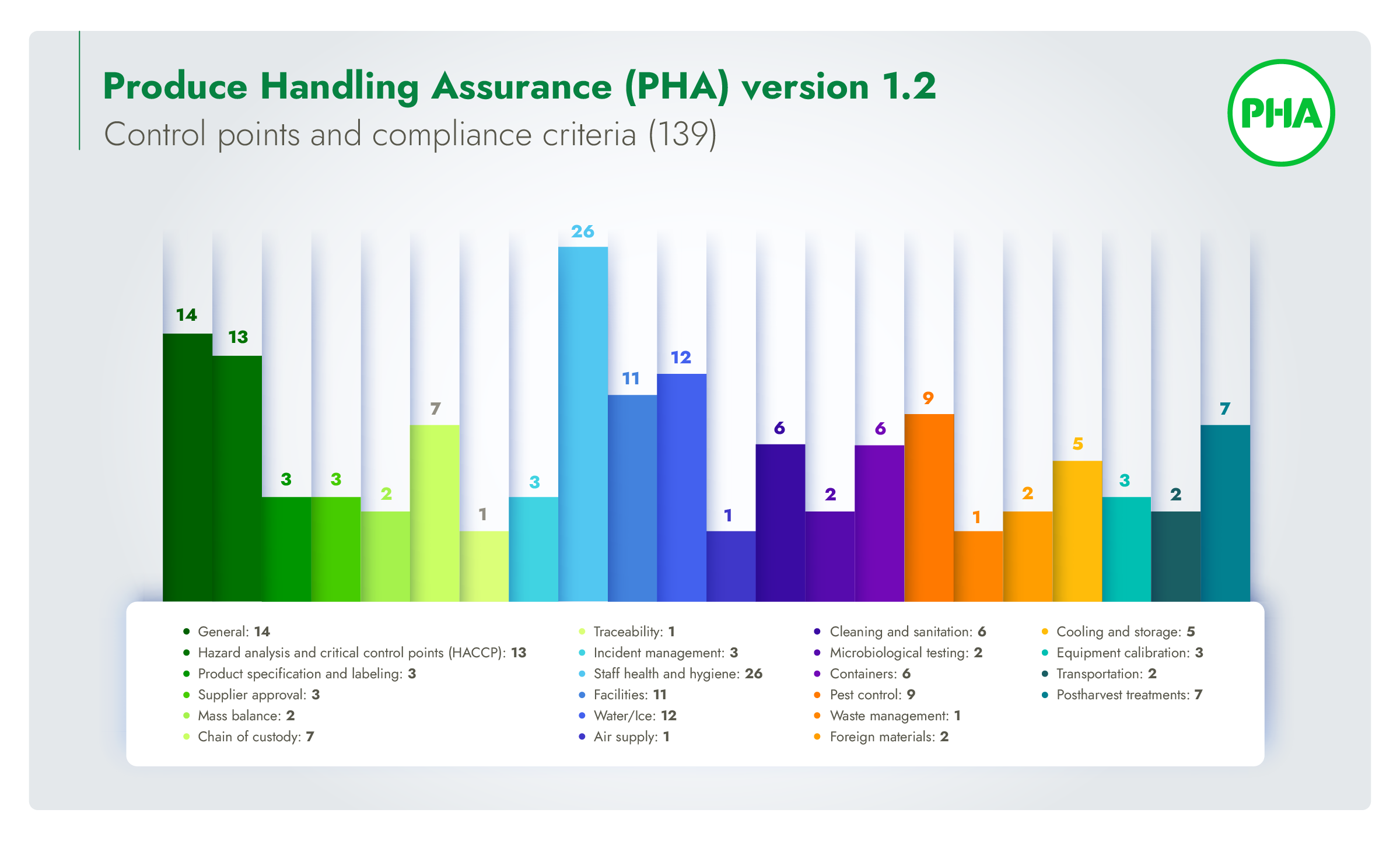

Which topics does PHA address?

PHA is designed for preprocessing stages only – it does not cover processing activities that significantly alter or transform crops from their original harvested state.

The standard has been developed together with sector stakeholders. Our approach to standard setting ensures that PHA remains robust, realistic, and cost-efficient while meeting the evolving demands of buyers.

Core topics in PHA v1.2 include:

Hazard analysis

Product specification and labeling

Mass balance, chain of custody, and traceability

Staff health and hygiene

Facilities, cleaning, and sanitation

Water/Ice/Steam, cooling, and storage

Microbiological testing

Pest control

Waste management

Transportation

Discover more about how PHA helps you address challenges in the agriculture sector.

| Preprocessing activities covered by PHA | Processing activities not covered by PHA |

|---|---|

| Cleaning | Addition of ingredients |

| Cooling/Hydrocooling | Cooking |

| Drenching/Rinsing | Cutting/Dicing/Shredding |

| Drying (natural only, without a dehydrator) | Dehydrating |

| Grading/Sorting | Freezing/Individual quick freezing |

| Hulling | Juicing/Pressing |

| Labeling | Milling |

| Loading | Mixing/Packaging of mixed salads |

| Packing/Repacking | Mixing |

| Shelling | Modified atmosphere packing (MAP) |

| Storage/Cold storage | Pasteurization |

| Threshing | Peeling |

| Trimming (foliage, husks, roots, stems) | Production of prepackaged ready-to-eat (RTE) foods |

| Washing | Roasting |

| Waxing | Vacuum packing |

Who should use PHA?

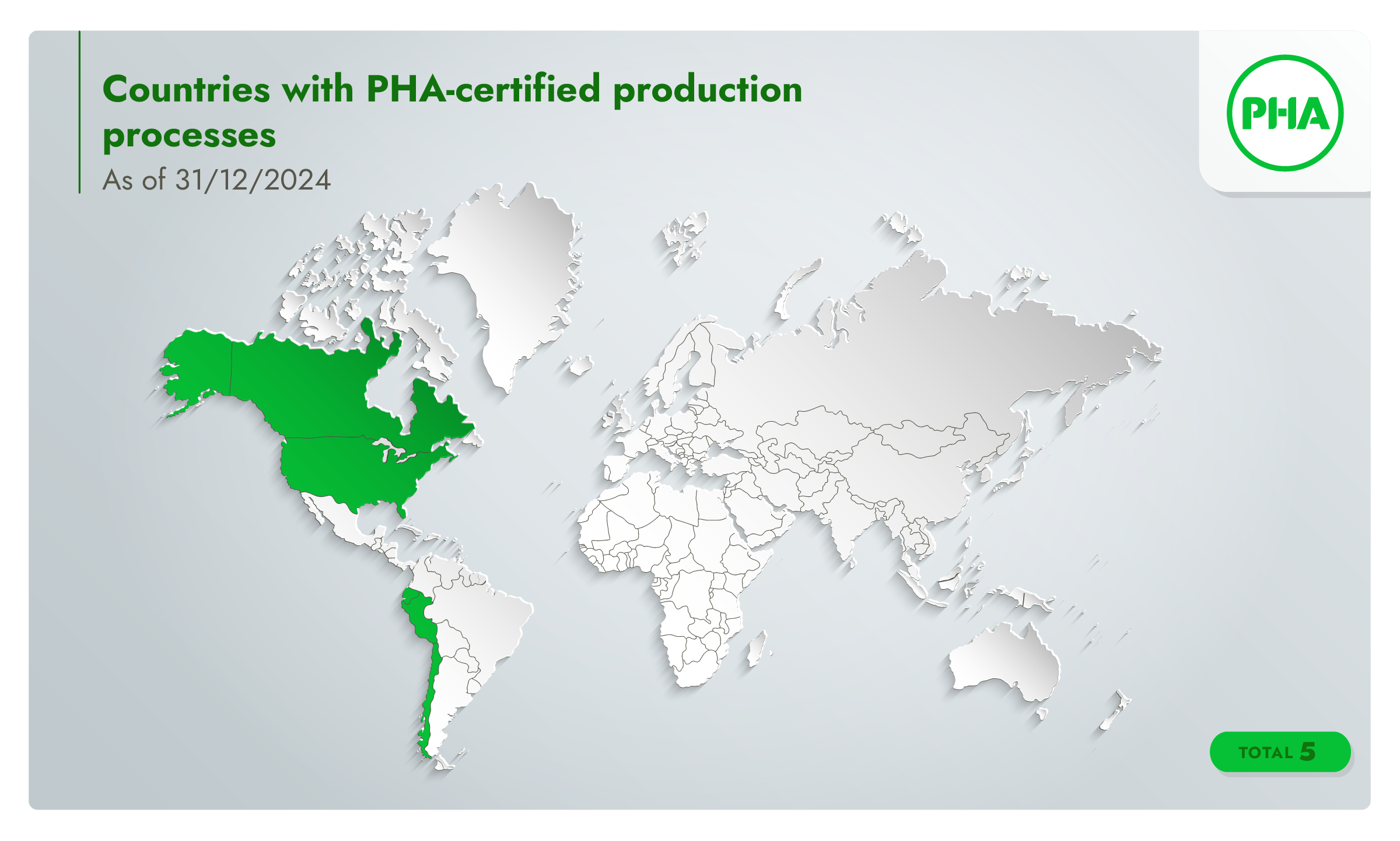

PHA is applicable globally to producers or postharvest operations that supply fruit and vegetables, combinable crops, or hops. Only the company legally responsible for packing, handling, or holding the crops can apply for PHA.

The standard is available for both the on-farm facilities of producers with GLOBALG.A.P. certification as well as independent operations that source from GLOBALG.A.P. certified production processes.

It offers GFSI-recognized certification (preprocessing only) for the following categories:

Packhouses

Cooling/Cold storage

Storage

Repacking

Open shed operations can get certification in any country where a GLOBALG.A.P. approved certification body (CB) conducts audits. Fully enclosed operations can get certification globally unless they are located in the European Union.

There is no group certification for PHA. Multisite certification is possible, and all sites of a legal entity (locations where products are handled) must be individually audited every year.

How does PHA work?

Compliance with the standard requirements is audited annually by an accredited and independent third-party CB. This CB audit may be combined with an IFA or HPSS CB audit (or an audit against a benchmarked scheme/checklist).

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a certificate valid for one year.

The certificate is awarded to the legal entity. Each site is certified individually and listed in the certificate annex.

The standard is composed of control points and compliance criteria (CPCCs). CPCCs are graded in two levels: Major Must and Minor Must.

Control points

Fundamentals that set the foundation of a GLOBALG.A.P. requirement

Written in question form

Compliance criteria

Methods that producers can use to demonstrate a control point to be true

Evidence required for demonstrating that the outcome is achieved

Read more about the audit process and standard requirements.

How is certification status verified?

Every producer registered in the GLOBALG.A.P. certification system is assigned a 13-digit GLOBALG.A.P. identification number (e.g., a GLOBALG.A.P. Number (GGN), or in the case of PHA, a Produce Handling Assurance Number (PHA-N)). This number allows verification of certification status in the GLOBALG.A.P. IT platform, upholding our rigorous transparency requirements throughout the supply chain.

Producers can control data access and privacy rights for audit reports, and the reports are not shared publicly or with third parties. This process is handled via your chosen CB.

GLOBALG.A.P. Chain of Custody

PHA-certified operations that complete section 6 of the checklist – “Chain of Custody (CoC)” – may also receive a CoC certificate, enabling market claims such as the use of the GGN label. Learn more about the benefits of CoC certification and the consumer facing GGN label initiative.

Corporate news and events have moved!

All the latest updates can now be found on the Agraya website – connecting people, ideas, and solutions across the global farming network.

Looking for technical news?

Technical news updates for core solutions can be found in our technical news libraries.

Meet international export requirements

Why choose Produce Handling Assurance?

Produce Handling Assurance (PHA) offers food safety and traceability certification for responsible postharvest activities. Applicable to fruit and vegetables, combinable crops, and hops, PHA is accepted by buyers in the US market and beyond who seek suppliers who comply with the requirements of the Global Food Safety Initiative (GFSI). The standard is available for both the on-farm facilities of producers with GLOBALG.A.P. certification as well as independent postharvest operations that source from GLOBALG.A.P. certified production processes, enabling both to demonstrate their efforts towards the implementation of Food Safety Modernization Act (FSMA) requirements.

Which industry challenges does PHA address?

Many retailers request an additional standalone postharvest certification that includes a specific focus on hazard analysis and critical control points (HACCP).

Before PHA, existing standards were developed for complicated postharvest operations such as processing and manufacturing. These standards were not appropriate for preprocessing activities such as packing, cooling, and storage.

Under FSMA, postharvest operations also require a solution for demonstrating compliance with the Produce Safety Rule (PSR) and the Current Good Manufacturing Practices (CGMP) aspects of the Preventive Controls for Human Food (PCHF) Rule.

Buyers are therefore seeking independent assurances to mitigate food safety and reputational risks at the postharvest stage, and supply chain stakeholders are faced with an increasing number of audits to satisfy them.

PHA can be implemented both as a standalone postharvest certification, and in combination with other GLOBALG.A.P. standards and add-ons for primary production.

Follow our five steps to certification to get started today.

What are the benefits for producers?

Reduce exposure to food safety and product safety reputational risks in postharvest processes.

Achieve independent third-party verification of safe, responsible, and traceable handling practices.

Comply with export market requirements, gaining access to buyers that seek GFSI-recognized packhouse certification.

Demonstrate your commitment to FSMA compliance for both the PSR and the PCHF Rule, with an audit report and certificate that can be provided to buyers as evidence of implementation.

Reduce audit duplication and the costs of certification by combining a PHA audit with other GLOBALG.A.P. standards and add-ons for primary production.

What are the benefits for supply chain stakeholders?

Reduce exposure to food safety and product safety reputational risks in postharvest processes.

Support stakeholder-driven smart farm assurance solutions – developed by the industry, for the industry – reducing audit duplication and the costs of certification.

Gain access to global suppliers with independently certified and GFSI-recognized postharvest processes.

Receive assurances on the implementation of FSMA requirements for both the PSR and the PCHF Rule.

Maintaining trust in GLOBALG.A.P. certification

The GLOBALG.A.P. Integrity Program was founded in 2008 as the first of its kind in food certification. Designed to ensure the consistent delivery and implementation of GLOBALG.A.P. standards and add-ons worldwide, the program monitors and assesses all aspects of the third-party certification process.

Which solutions can be combined with PHA?

PHA can be implemented by producers with GLOBALG.A.P. certified primary production processes and independent postharvest operations that source from GLOBALG.A.P. certified production processes. The GLOBALG.A.P. portfolio also offers further solutions to address FSMA requirements for producers based in or exporting to the US market.

Learn more about GLOBALG.A.P. smart farm assurance solutions.

You may also be interested in...

Integrated Farm Assurance for fruit and vegetables

IFA is a global standard that aims to promote safer and more responsible farming practices in fruit and vegetable production.

Integrated Farm Assurance for combinable crops

IFA is a global standard that aims to promote safer and more responsible farming practices in combinable crops production.

Harmonized Produce Safety Standard

HPSS is a GFSI-recognized, FSMA-aligned food safety standard based on the Combined Harmonized Standard from the IFPA’s Produce GAP Harmonization Initiative.

Ready to get started?

Use our Smart Checklist Builder to easily understand which GLOBALG.A.P. smart farm assurance solutions are recommended for your production practices and generate a personalized checklist for your self-assessment.

Your guide to implementation

How to prepare for a Produce Handling Assurance audit

Learn more about the key documents and fee structure of Produce Handling Assurance (PHA). Follow our five steps to certification for an overview of the certification process, and find a GLOBALG.A.P. approved certification body (CB) in your area to get started.

Implementation and CB audit process

How does the CB audit process work?

PHA compliance is audited annually by accredited and independent third-party CBs. For producers with existing GLOBALG.A.P. certification, compliance with the PHA requirements can be audited together with the Integrated Farm Assurance (IFA) or Harmonized Produce Safety Standard (HPSS) audit.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a certificate valid for one year.

The CB is responsible for uploading the audit report and maintaining the accuracy of producer data in the GLOBALG.A.P. IT platform.

Producers will be audited annually by the CB as part of the renewal process.

Which documents are required?

PHA general regulations: Rules that define how the certification process works, from the scope of the standard to the audit requirements.

Control points and compliance criteria (CPCCs): Control points are the fundamental requirements for each standard. They are written in question form and are accompanied by corresponding compliance criteria that detail how a producer must demonstrate compliance.

Checklist: The full list of CPCCs as used by CB auditors, enabling producers to conduct a self-assessment in preparation for the CB audit.

Which version of PHA is currently valid?

PHA is currently valid in version 1.2.

PHA v1.2 was published in July 2020 and replaced all previous versions in October 2020. The PHA general regulations underwent a minor update to v1.2-1 in October 2021, becoming applicable on 1 January 2022.

PHA v2 is currently in development and is scheduled for publication in 2026.

The FAQ contains more information on documents, certification renewal, and more.

What are the PHA standard requirements?

CPCCs are graded in two levels: Major Must and Minor Must.

To achieve certification, producers must comply with 100% of the Major Musts and at least 95% of the Minor Musts.

Corrective actions must be proposed for all non-compliances and submitted to the CB within the specified period.

Non-compliances must then be verified as corrected and compliant by the CB before a certificate can be issued.

How much does PHA certification cost?

Each farm/packhouse operation is unique, and the total costs of certification depend on a combination of factors such as farm size, number of sites, location, necessary preparation measures (such as establishing new procedures, updating equipment, etc.), and more. PHA contains three cost elements:

Implementation costs: Incurred by the producer/postharvest operation to prepare for the CB audit

CB service fees: Determined and invoiced by the CB to cover audit time and travel costs

GLOBALG.A.P. registration and certificate license fees: Calculated based on producer sites and invoiced by the CB

The GLOBALG.A.P. fee table contains full information on the fee structure for each standard and add-on.

Five steps to certification

You will need the PHA general regulations, the PHA CPCCs, and the checklist. All of the required documents are available online, for free, and in multiple languages. They are linked below and can also be found in the GLOBALG.A.P. document center.

Use the documents to guide the implementation of the standard requirements, and then

conduct a self-assessment using the checklist. Our worldwide network of Registered Trainers

can also provide assistance during audit preparations.

Search the list of GLOBALG.A.P. approved CBs by region, country, scope, and status. Contact the CB of your choice and request an audit. Note that the GLOBALG.A.P. fee table does not cover CB service fees such as audit time or travel costs to your site.

The CB will conduct the audit and upload the results to the GLOBALG.A.P. IT platform. Any non-compliances which are detected during the CB audit must be corrected within the specified period and verified by the CB before a certificate can be issued.

Once all requirements are met and verified by the CB, they will issue your PHA certificate. Your certification status is then publicly visible in the GLOBALG.A.P. IT platform for transparency in the market.

Key documents

The three most relevant documents are linked below. Click ‘view more’ to see further related documents. Remember to always check with your CB that you have all necessary documents prior to audit.

PHA addendum to GR

GLOBALG.A.P. general regulations

V1.2-1

English | Last updated: 29/11/2024

GLOBALG.A.P. general regulations

V1.2-1

English | Last updated: 29/11/2024

GLOBALG.A.P. general regulations outline the framework of the certification system, including the role and relationship of the GLOBALG.A.P. Secretariat and certification bodies, and provide context for implementing checklist content.

PHA

Checklists

V1.2

English | Last updated: 29/11/2024

xlsx

Checklists

V1.2

English | Last updated: 29/11/2024

xlsx

Checklists are documents containing standard/add-on principles and criteria which are used during the audit/assessment to check whether compliance is achieved. They may also be used to conduct self-assessments.

PHA

Principles and criteria (P&Cs) (CPCCs)

V1.2

English | Last updated: 29/11/2024

Principles and criteria (P&Cs) (CPCCs)

V1.2

English | Last updated: 29/11/2024

Principles and criteria are a complete list of the requirements for a given standard or add-on. The foundational requirements each detail an outcome that must be achieved, and the corresponding ways in which compliance can be demonstrated.

GLOBALG.A.P. approved CBs

The list of GLOBALG.A.P. approved CBs can be filtered by region, country, scope, and status. Click a CB to find more information and contact details.

If you do not filter your search, or filter only according to region and/or country, your search results will also show CBs that offer certification against benchmarked schemes, but which may not have approval for any GLOBALG.A.P. standards and add-ons.

Capacity building

Need assistance with the certification process? Our capacity-building program offers a range of options for training, consultation, and more!

A brief history of PHA

Following demand from stakeholders for a standalone, GFSI-recognized postharvest assurance standard, the development of PHA begins in March 2018. GLOBALG.A.P. integrates the GFSI v7.2 (Part III, Scope D – Pre-Processing Handling of Plant Products) requirements during the development process.

The draft PHA v1 undergoes two public consultations and is finalized and published in September 2018. The GFSI benchmarking process is completed in December 2018.

PHA is updated to v1.1 and published in April 2019, replacing v1 in July. By the end of the year, the first 12 producers are under PHA certification.

The standard is revised again and updated to v1.2 in July 2020 in anticipation of new GFSI requirements (GFSI v2020), replacing v1.1 in October.

In May 2021, PHA achieves renewed recognition from GFSI against v2020.1 of their benchmarking requirements. The PHA general regulations are updated to v1.2-1 in October 2021, and by the end of the year there are 25 producers under certification.

The updated PHA general regulations (v1.2-1) are published in January 2022 following the annual GFSI desk review.

The development of PHA v2 begins, with the first public consultation period scheduled for Q2 2025.

FAQ

PHA addresses current good manufacturing practices, hazard analysis and preventive controls, traceability and segregation, and overall food safety management practices. This includes supplier management, food safety–related incidents, and additional requirements for site, personnel, and production management.

Postharvest preprocessing activities covered by PHA include:

Cleaning

Cooling/Hydrocooling

Drenching/Rinsing

Drying (natural only, no dehydrating)

Grading/Sorting

Hulling

Labeling

Loading

Packing/Repacking

Shelling

Storage/Cold storage

Threshing

Trimming (foliage, husks, roots, stems)

Washing

Waxing

PHA covers only preprocessing activities. These can be defined under four main categories: cooling, packing, repacking, and storage/distribution. The standard does not cover activities that significantly alter or transform crops from their original harvested state.

Postharvest activities not covered by PHA include:

Addition of ingredients

Cooking

Cutting/Dicing/Shredding

Dehydrating

Freezing/Individual quick freezing

Juicing/Pressing

Milling

Mixing/Packaging of mixed salads

Mixing

Modified atmosphere packing (MAP)

Pasteurization

Peeling

Pre-packaged ready-to-eat (RTE) foods

Roasting

Vacuum packing

Although many of the GLOBALG.A.P. primary production standards cover basic on-site postharvest activities, some markets prefer a targeted audit and separate certificate. PHA goes beyond the IFA requirements in the following ways:

Workers and training:

Includes allergen training as part of the risk assessment

Requires food safety personal protective equipment (PPE) to be stored appropriately, and designated storage for worker belongings

Introduces non-retaliatory food safety violations requirement

Buildings and equipment:

Has a higher level of detail for sanitary facilities

Ensures suitable design, construction, and layout of facilities, buildings, operations, and equipment

Provides robust details for properly maintaining equipment including coolers, ventilation, lighting, and other sources of potential contamination

Includes details for preventive maintenance of equipment and vehicles along with procedures for temporary repairs

Requires proper tool identification

Adds specificity to calibrations and incorporates foreign material devices

Pre-operational checks are mandatory

Provides details for the maintenance of grounds

Requires more details to be provided for postharvest water delivery systems, not only final rinse water

Contains explicit requirement for maintenance of sewage disposal systems

Requires more details for cleaning procedures and frequency, as well as records requirements

Introduces robust pest control requirements including spacing, location, and verification of records

Includes additional requirements specific to storage, including cold and iced storage

Hazards:

Directly includes hazard analysis and critical control points, where applicable, including flow diagram and HACCP team

Expands the foreign materials category by addressing physical and chemical hazards in detail

Assigns more responsibility to the operations regarding water treatments for reused water

Contains more specific criteria regarding food contact surfaces

Provides more details for microbiological testing, including an annex to support operations in making decisions about environmental monitoring

Suppliers:

Includes customer requirements and specifications

Includes supplier approval

PHA incorporates Food Safety Modernization Act (FSMA) requirements from both the Produce Safety Rule (PSR) (all postharvest requirements) and the Preventive Controls for Human Food (PCHF) Rule (requirements for facilities that handle, store, and pack raw agricultural commodities, including the Current Good Manufacturing Practices (CGMPs), preventive controls, and supplier approvals).

As PHA was developed after the publication of FSMA and both of the relevant rules, GLOBALG.A.P. was able to understand the intention of these requirements and how they will be enforced by the US Food and Drug Administration (FDA).

Please note that the PHA certificate is not an assurance or guarantee of FSMA compliance, as legal compliance can only be determined by a regulatory authority such as the FDA.

For open shed operations, the PHA standard is available in all regions.

For fully enclosed operations, the PHA standard is available in all regions except the European Union.

The geographic availability of PHA has been determined based on expressed market need and consideration for suppliers who are seeking compliance with Food Safety Modernization Act (FSMA) requirements for the US market.

We believe that all hazards must be identified and assessed for their risk level through a risk assessment process. This means that all hazards that present a risk must be mitigated through hazard control or preventive control procedures.

We additionally agree with the majority of the food safety industry that pre-processed whole commodities need not undergo a kill step for microbial hazards.

Therefore, there are no CCPs for preprocessed whole commodities. Despite this, there are some controls (such as water treatment or metal detection) that buyers may require, and these are included. All other mitigation practices relevant to the Current Good Manufacturing Processes (CGMPs) are included in the PHA checklist.

CoC ensures supply chain traceability and transparency. Elements of this standard are included in the checklist so that PHA-certified operations may make claims about the origins of products from certified production. If an operation makes no GLOBALG.A.P. claims, this section is not applicable during the PHA audit.

See the GLOBALG.A.P. trademarks use: policy and guidelines document for more information.

PHA v1.2 was published on 15 July 2020 and replaced all previous versions in October 2020. The PHA general regulations underwent a minor update to v1.2-1 in October 2021, becoming applicable on 1 January 2022. This version is benchmarked to GFSI v2020.1.

Each farm/operation is unique, and the total cost of certification depends on a combination of factors such as size, location, existing policies and processes, etc. The invoice from your certification body (CB) will include CB service fees to cover expenditures (determined by the CB) and the GLOBALG.A.P. registration and certificate license fee.

Download the GLOBALG.A.P. fee table to learn more.

PHA documents are currently available in:

English

Spanish

All documents are located in the GLOBALG.A.P. document center. More languages are added based on demand – please contact us with requests.

PHA compliance is audited annually. The certification body (CB) audit must take place within the validity period of the current certificate in order for you to retain your certification status. Contact your CB to request an audit.

When developing our standards and add-ons, we aim to receive as much input and feedback as possible. With producers based in more than 130 countries around the world and stakeholders covering every part of the value chain, our standard-setting process ensures that our solutions are both fit for purpose now and built with the future in mind.

We offer public consultation periods for draft standard documents that are created by our technical experts. This helps to uphold transparency in the development, revision, and decision-making processes. The web page on standard setting outlines the development process.

Technical questions can be addressed to standard_support@agraya.com. Your query will be forwarded to the relevant technical expert.

The GLOBALG.A.P. Academy offers public trainings on our portfolio of smart farm assurance solutions, while our worldwide network of Registered Trainers offers authorized trainings and other services. See the GLOBALG.A.P. Academy course catalog or find a Registered Trainer for more information.

The CB auditor requirements for PHA are detailed in Part III of the PHA general regulations.

Learn more about how to become a GLOBALG.A.P. approved CB or extend your auditing scope.

No, certification to a GLOBALG.A.P. standard/holding a GLOBALG.A.P. certificate is not the same as being a GLOBALG.A.P. Community Member.

GLOBALG.A.P. Community Membership is a paid partnership opportunity, offering a variety of benefits including the ability to support the development of GLOBALG.A.P. standards and add-ons, contribute to the GLOBALG.A.P. governance structure, and access discounted services.

Learn more about how to become a GLOBALG.A.P. Community Member.

GLOBALG.A.P. trademarks may be used in a strictly B2B context and must be accompanied by a GLOBALG.A.P. identification number (e.g., GLOBALG.A.P. Number (GGN)/Produce Handling Assurance Number (PHA-N)) or a QR code to a producer’s certification status in the GLOBALG.A.P. IT platform. The trademarks should never appear to consumers, for example on product packaging.

Operations that are PHA-certified may use their PHA-N on product labeling. Operations that are PHA-certified and also comply with the Chain of Custody (CoC) section of the standard may use the PHA-N as well as the GLOBALG.A.P. Number (GGN) of the product on labeling after harvest.

Download the GLOBALG.A.P. trademarks use: policy and guidelines and the GLOBALG.A.P. trademarks use: FAQ for comprehensive information on rules and use cases.

Questions about FSMA?

See our dedicated FAQ for information on FSMA rules for the fresh produce industry, including producers, postharvest facilities, importers, and certification bodies.

Contact us

For technical/interpretation questions, please contact us at standard_support@agraya.com.

For questions about the audit process or the GLOBALG.A.P. IT platform, please contact us at customer_support@globalgap.org.