Core solution

Harmonized Produce Safety Standard

The Harmonized Produce Safety Standard (HPSS) is a robust food safety standard that includes the International Fresh Produce Association (IFPA) Produce GAP Harmonization Initiative’s Combined Harmonized Standard. It also contains additional content that is necessary to achieve certification recognized by the Global Food Safety Initiative (GFSI).

Driving harmonization in food safety standards

What is the Harmonized Produce Safety Standard?

The Harmonized Produce Safety Standard (HPSS) is a global food safety standard covering both preharvest and postharvest production processes for fruit and vegetables and combinable crops. Aligned with the requirements of the Food Safety Modernization Act (FSMA) Produce Safety Rule (PSR), the standard is applicable to producers who supply the US market. It offers a cost-efficient alternative to the flagship Integrated Farm Assurance (IFA) standard, as it only requires food safety elements. HPSS is the result of a collaboration with the International Fresh Produce Association (IFPA). Thanks to this collaboration, the GLOBALG.A.P. Secretariat can offer the only edition of the Produce GAP Harmonization Initiative’s Combined Harmonized Standard that is fully recognized by the Global Food Safety Initiative (GFSI) for fruit and vegetables. Applied in accordance with the GLOBALG.A.P. general regulations and integrity system, HPSS reduces audit fatigue in the supply chain by combining the GFSI v2020.1 benchmarking requirements for scope BI “Farming of Plants (Other Than Grains and Pulses)” into the same audit checklist.

HPSS at a glance

Offers GFSI-recognized

food safety-only certification (for fruit and vegetables) while reducing industry duplication

Provides audit options

for a wide variety of farm sizes and types, including smallholders and producer groups

Covers the entire production process,

from preharvest activities through to postharvest handling

Results in

an accredited, third-party certificate which can be provided to value chain stakeholders such as importers

Includes verbatim

the Combined Harmonized Standard aligned with the PSR

Designed specifically

for global fruit and vegetable and combinable crop producers who supply the US market

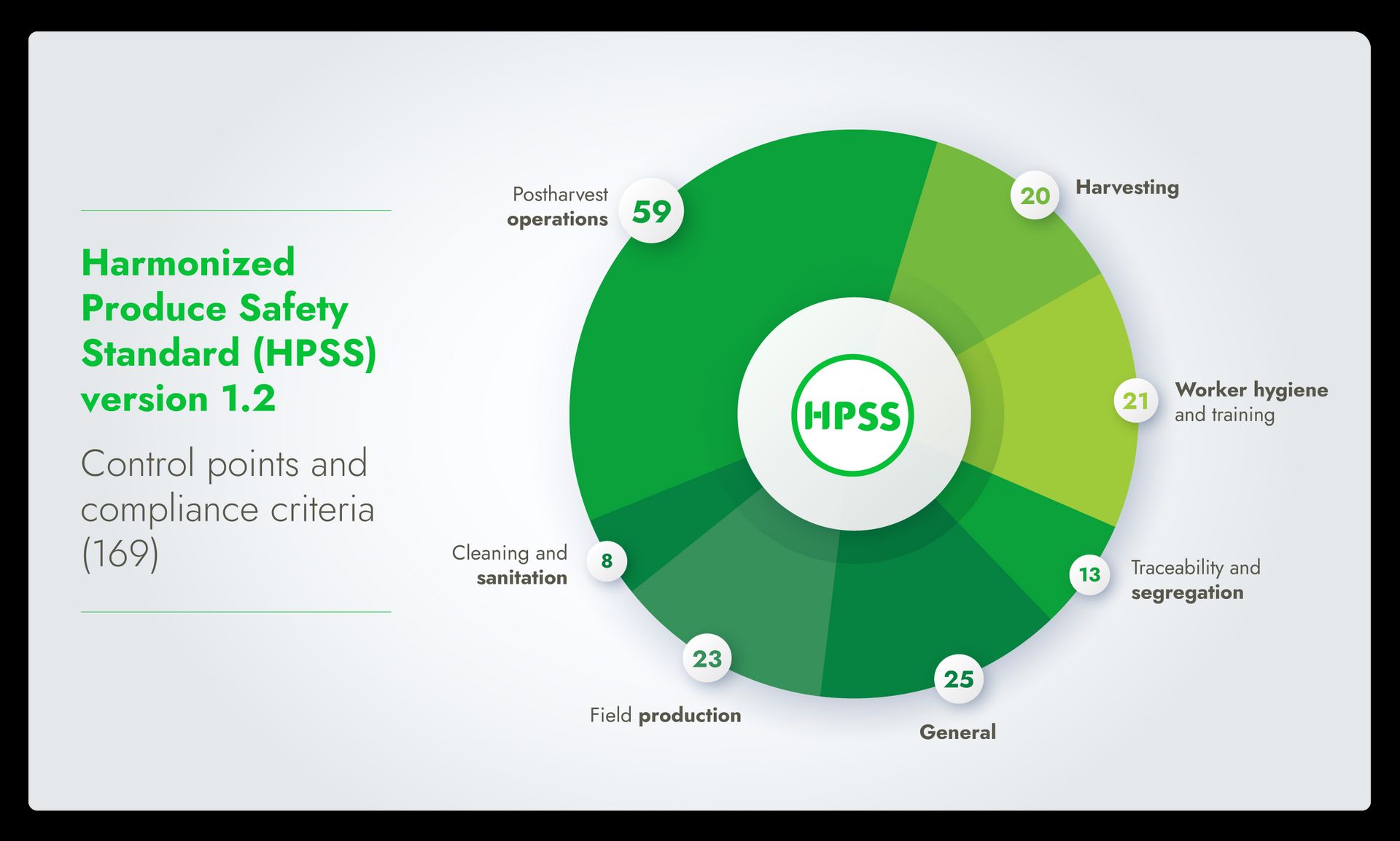

Which topics does HPSS address?

HPSS covers both preharvest and postharvest aspects of production. It consists primarily of the standards that collectively form the Produce GAP Harmonization Initiative’s Combined Harmonized Standard v2.0:

Field Operations and Harvesting Harmonized Standard v2.0

Post-Harvest Operations Harmonized Standard v2.0

For fruit and vegetable farms, additional HPSS control points specific to the BI scope of GFSI v2020.1 have been integrated into the standard. Traceability criteria unique to GLOBALG.A.P. certification are also included for both fruit and vegetables and combinable crops. HPSS is continuously developed in collaboration with the IFPA Harmonized Standard Technical Working Group and Calibration Committee to ensure that it remains robust, realistic, and cost-efficient for producers while meeting the evolving demands of buyers.

Core topics in HPSS v1.2 include:

Field production

Harvesting

Transportation (field to storage or packing house)

Postharvest operations

Transportation (packing house to customer)

Complaints

Food defense

Food fraud mitigation

Traceability and segregation

Mass balance

Discover more about how HPSS helps you address challenges in the agricultural sector.

Who should use HPSS?

HPSS is available globally for fruit and vegetable and combinable crop producers who supply the US market. It offers certification options for both individual producers (single site and multisite producers) and producer groups, including smallholders. Producers can get certification in any country where a GLOBALG.A.P. approved certification body (CB) conducts audits.

Producers can choose HPSS if they require a standard that only addresses food safety. GLOBALG.A.P.’s flagship Integrated Farm Assurance (IFA) standard – available for the product categories fruit and vegetables, combinable crops, and more – adopts a broader, holistic approach which also covers the key topics of environmental sustainability and workers’ well-being.

Please note that fruit and vegetables is the only product category for which HPSS certification is recognized by GFSI. Producers of pulses, grains, and other crops that are machine-harvested (classified as “combinable crops” by the GLOBALG.A.P. Secretariat) can get HPSS certification, but the resulting certificate is not recognized by GFSI.

How does HPSS work?

Compliance with the standard requirements is audited annually by an accredited and independent third-party CB.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a certificate valid for one year.

The standard is composed of control points and compliance criteria (CPCCs). CPCCs are all graded at Major Must level, meaning that compliance with each point is mandatory.

Control points

Fundamentals that set the foundation of a GLOBALG.A.P. requirement

Written in question form

Compliance criteria

Methods that producers can use to demonstrate compliance

Evidence required for demonstrating that the outcome is achieved

Read more about the audit process and standard requirements.

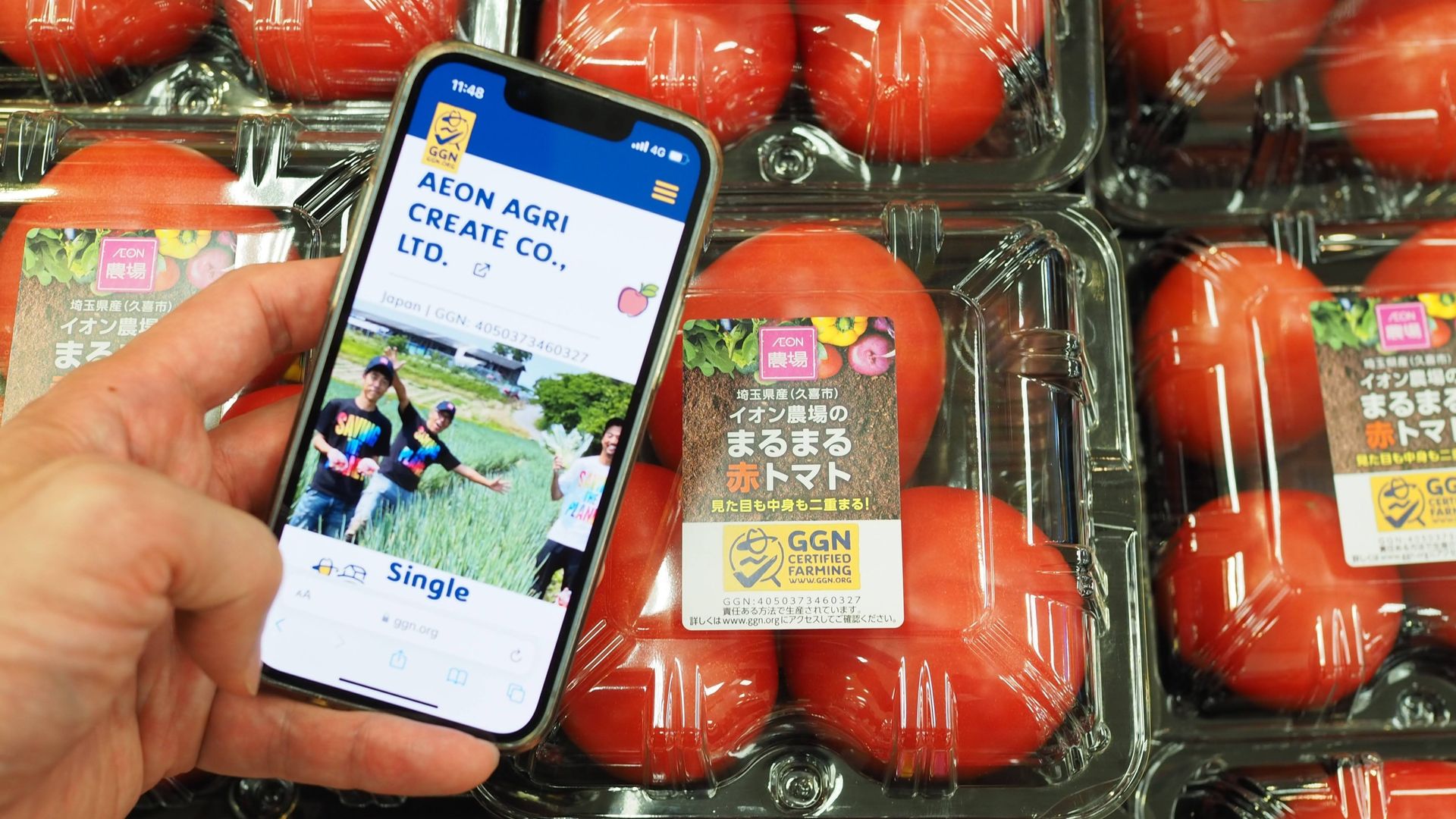

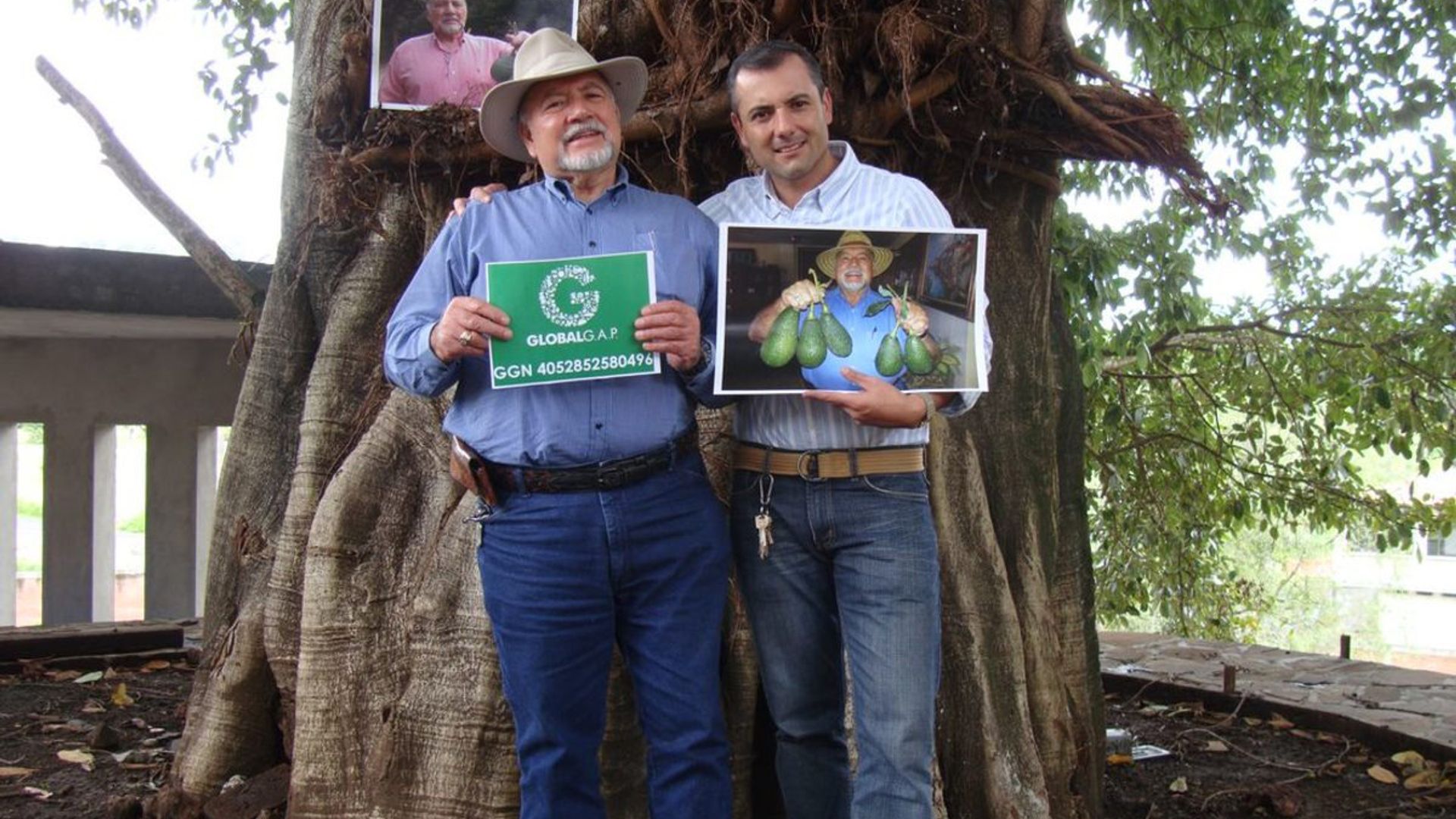

How is certification status verified?

Every producer registered in the GLOBALG.A.P. certification system is assigned a 13-digit GLOBALG.A.P. identification number (in this case a Harmonized Produce Safety Standard GLOBALG.A.P. Number (HPSS-GGN)). This number allows real-time verification of certification status in the GLOBALG.A.P. IT systems, upholding our rigorous transparency requirements throughout the supply chain.

Producers can control data access and privacy rights for audit reports, and the reports are not shared publicly or with third parties. This process is handled via your chosen CB.

What is the difference between IFA and HPSS?

| IFA | HPSS |

|---|---|

| Developed by stakeholders, for stakeholders in consultation with technical experts, technical committees, and focus groups, and requires adoption by the GLOBALG.A.P. Advisory Board. | Developed by US stakeholders in the IFPA Harmonized Standard Technical Working Group, with additional content supplemented by the GLOBALG.A.P. Secretariat as necessary for GFSI recognition. |

| Adopts a holistic approach to certification, covering the key topics of food safety, environmental sustainability, workers’ well-being, animal welfare, and traceability. | Only contains food safety criteria, supplemented with GLOBALG.A.P. traceability requirements. |

| Available for two scopes (plants and aquaculture) that contain multiple product categories (such as fruit and vegetables). | Only available for the product categories of fruit and vegetables and combinable crops. |

| Can be combined with the portfolio of GLOBALG.A.P. add-ons to core solutions, which are targeted at specific aspects of production and the supply chain. | Cannot be combined with the portfolio of GLOBALG.A.P. add-ons to core solutions, although CBs may offer commodity-specific metrics from the IFPA. |

| Audited by third-party, accredited, and GLOBALG.A.P. approved CBs. It results in a certificate that demonstrates responsible farming practices. | Audited by third-party, accredited, and GLOBALG.A.P. approved CBs. It results in a certificate that demonstrates responsible food safety practices. |

| Requires the development of a food safety risk assessment. Under IFA, these protocols are called “mitigation procedures” and must take the form of a written policy. | Requires the development of a food safety risk assessment. Under HPSS, this is called a “food safety plan,” but not all documents take the form of a written policy. |

| Contains not only control points and compliance criteria, but also guidelines which provide producers with guidance on potential hazards to be identified and possible mitigation strategies. | Rather than guidance, the Combined Harmonized Standard refers to industry best practices. Auditing rules are not mandated, but set by each scheme operator, e.g., by the GLOBALG.A.P. Secretariat. |

Is HPSS compliant with the PSR?

Facilitated by the IFPA, the Harmonized Standard Technical Working Group aligned the Combined Harmonized Standard with the PSR in 2016.

The US Food and Drug Administration (FDA) released a statement in 2018 stating that the US Department of Agriculture’s Harmonized Good Agricultural Practices Audit Program (H-GAP) is aligned with the PSR. As this is formed of the same Combined Harmonized Standard that is included in full in HPSS, there is reasonable assurance that HPSS is also aligned.

Latest news

11 April 2024

New GLOBALG.A.P. webinar series: A guide to IFA v6 transition

Hosted by GLOBALG.A.P. experts, our latest free webinar series is designed to help producers transition seamlessly to IFA version 6 for flowers and ornamentals, fruit and vegetables, and aquaculture. Find your webinar today!

26 March 2024

NSF Certification UK Ltd awards the first IFA v6 Smart certificate

Italian fruit producer Roberto Faillace is the first to receive a certificate for IFA v6 Smart. Learn more about his experience transitioning to the latest version of GLOBALG.A.P.’s flagship standard.

Looking for technical news?

Technical news updates for core solutions can be found in our technical news libraries.

Demonstrate your commitment to food safety

Why choose the Harmonized Produce Safety Standard?

The Harmonized Produce Safety Standard (HPSS) is a streamlined food safety standard that covers the entire production process and is recognized by the Global Food Safety Initiative (GFSI) for the production of fruit and vegetables. The standard is accepted by retailers in the US market and beyond who seek GFSI-compliant suppliers, with the HPSS certificate demonstrating both robust responsible farming practices and producer efforts towards the implementation of the requirements of the Food Safety Modernization Act (FSMA).

Which industry challenges does HPSS address?

According to the US Centers for Disease Control and Prevention, approximately 48 million people in the United States – one in six – suffer from foodborne illnesses each year.

FSMA was introduced by the US Food and Drug Administration (FDA) to shift the attention from responding to food safety issues to preventing them, viewing the topic as not only a public health problem but also a threat to the long-term sustainability of the food supply chain.

The FDA now requires all importers of fresh produce to the US market to apply the FSMA rules through the Foreign Supplier Verification Program (FSVP) – ensuring that these products meet consistent science-based standards for food safety, preventive controls, and more.

In 2009, the International Fresh Produce Association (IFPA) founded the Produce GAP Harmonization Initiative with the goal to “reduce audit fatigue and allow operations to focus their food safety resources on achieving food safety, rather than passing audits.”

Combined with growing requests from GLOBALG.A.P. stakeholders for a dedicated food safety standard that is recognized by GFSI, HPSS was created to offer the Produce GAP Harmonization Initiative’s Combined Harmonized Standard via the GLOBALG.A.P. certification system – achieving the goal of “one audit by a credible third party, acceptable to all buyers.”

Follow our five steps to certification to get started today.

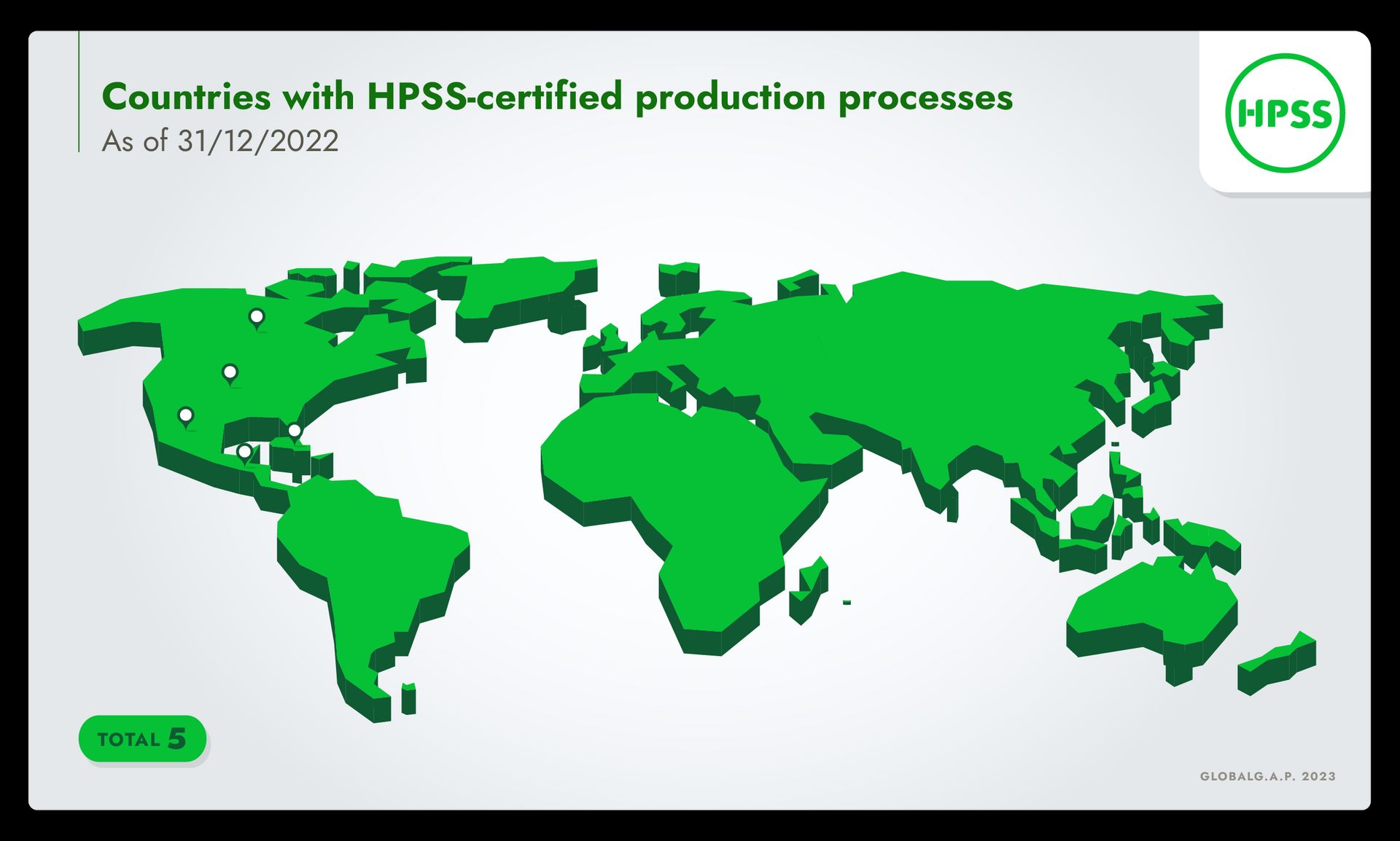

HPSS in numbers (as of 31/12/2022)

197

producers under certification

5

countries with certified production processes

26,298

hectares of certified production

What are the benefits for producers?

Improve food safety-related farm management and mitigate reputational risks.

Achieve compliance with a globally recognized standard, benchmarked by GFSI for fruit and vegetables, that fulfills international supply chain requirements.

Apply our smart farm assurance solutions on a wide range of farm types and sizes and access certification options for both individual producers and producer groups.

Choose from an extensive worldwide network of accredited, GLOBALG.A.P. approved certification bodies (CBs).

Provide the certificate to importers, retailers, and other value chain stakeholders as third-party verified evidence of your efforts towards FSMA implementation.

What are the benefits for supply chain stakeholders?

Support industry-driven smart farm assurance solutions – developed by the sector, for the sector – that reduces the audit burden and enables buyers to easily identify suppliers that fulfill their requirements.

Mitigate food safety–related reputational risks, with added GLOBALG.A.P. traceability requirements to protect product integrity.

Source from a growing pool of suppliers with certified production processes globally, with easy certification verification in the GLOBALG.A.P. IT systems.

Receive third-party verified evidence of supplier efforts towards FSMA implementation.

Maintaining trust in GLOBALG.A.P. certification

The GLOBALG.A.P. Integrity Program was founded in 2008 as the first of its kind in food certification. Designed to ensure the consistent delivery and implementation of GLOBALG.A.P. standards and add-ons worldwide, the program monitors and assesses all aspects of the third-party certification process.

Which solutions can be combined with HPSS?

As HPSS is based on the Produce GAP Harmonization Initiative’s Combined Harmonized Standard, it cannot be combined with GLOBALG.A.P. add-ons to core solutions. However, the GLOBALG.A.P. portfolio of smart farm assurance solutions offers two other solutions that address the FSMA requirements for producers based in or supplying the US market.

Learn more about GLOBALG.A.P. smart farm assurance solutions.

You may also be interested in...

Integrated Farm Assurance for fruit and vegetables

IFA is a global standard for safe and responsible farming practices in fruit and vegetable production.

Produce Handling Assurance

PHA is a GFSI-recognized, FSMA-aligned food safety and traceability standard for postharvest activities such as the packing, handling, and storage of crops.

Food Safety Modernization Act Produce Safety Rule add-on

The FSMA PSR add-on addresses FDA requirements for the import of fruit and vegetable products to the US market.

Ready to get started?

Use our Smart Checklist Builder to easily understand which GLOBALG.A.P. smart farm assurance solutions are recommended for your production practices and generate a personalized checklist for your self-assessment.

Your guide to implementation

How to prepare for a Harmonized Produce Safety Standard audit

Learn more about the key documents and fee structure of the Harmonized Produce Safety Standard (HPSS). Follow our five steps to certification for an overview of the certification process, and find a GLOBALG.A.P. approved certification body (CB) in your area to get started.

Implementation and CB audit process

How does the CB audit process work?

HPSS compliance is audited annually by accredited and independent third-party CBs.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a certificate valid for one year.

The CB is responsible for uploading the audit report and maintaining the accuracy of producer data in the GLOBALG.A.P. IT systems.

Producers will be audited annually by a CB as part of the renewal process.

Which documents are required?

GLOBALG.A.P. general regulations and its addendum for HPSS: Rules that define how the certification process works, from the scope of the respective standard to the audit requirements.

Control points and compliance criteria (CPCCs): Control points are the fundamental requirements for each standard. They are written in question form and are accompanied by corresponding compliance criteria that detail how a producer must demonstrate compliance.

Checklist: The full list of CPCCs as used by CB auditors, enabling producers to conduct a self-assessment in preparation for the CB audit.

Which version of HPSS is currently valid?

HPSS is currently valid in version 1.2.

HPSS v1.2 was published in August 2020 and became obligatory in November 2020. In May 2021, it achieved renewed recognition from the Global Food Safety Initiative (GFSI) for fruit and vegetables, having been successfully benchmarked against GFSI’s Benchmarking Requirements Version 2020.1. The standard first completed the GFSI benchmarking process in 2016.

The revision of the standard for v1.3 is currently ongoing and is due for publication in 2024. Visit our standard setting web page for more information about the revision process.

The FAQ contains further information on documents, certification renewal, and more.

What are the HPSS requirements?

CPCCs are all graded as Major Musts.

To achieve certification, producers must comply with 100% of the Major Musts.

Corrective actions must be proposed for all non-compliances and submitted to the CB within the specified period.

Non-compliances must then be verified as corrected and compliant by the CB before a certificate can be issued.

How much does HPSS certification cost?

Each farm is unique, and the total costs of certification depend on a combination of factors such as farm size, number of sites, location, necessary preparation measures (such as establishing new procedures), and more. HPSS contains three cost elements:

Implementation costs: Incurred by the producer to prepare for the CB audit

CB service fees: Determined and invoiced by the CB to cover audit time and travel costs

GLOBALG.A.P. registration and certificate license fee: Calculated based on farm size and invoiced by the CB

The GLOBALG.A.P. fee table contains full information on the fee structure for each standard and add-on.

Five steps to certification

You will need the GLOBALG.A.P. general regulations and its addendum for HPSS, the HPSS CPCCs, and the checklist. All the required documents are available online, for free, and in multiple languages. They are linked below and can also be found in the GLOBALG.A.P. document center.

Use the documents to guide the implementation of the standard requirements, and then

conduct a self-assessment using the checklist. Our worldwide network of Registered Trainers

can also provide assistance during audit preparations.

Search the list of GLOBALG.A.P. approved CBs by region, country, scope, and status. Contact the CB of your choice and request an audit. Note that the GLOBALG.A.P. fee table does not cover CB service fees such as audit time or travel costs to your site.

The CB will conduct the audit and upload the results to Audit Online Hub. Any non-compliances which are detected during the CB audit must be corrected within the specified period and verified by the CB before a certificate can be issued.

Once all requirements are met and verified by the CB, they will issue your HPSS certificate. Your certification status is then publicly visible in the GLOBALG.A.P. IT systems for transparency in the market.

Key documents

The three most relevant documents are linked below. Click ‘view more’ to see further related documents. Remember to always check with your CB that you have all necessary documents prior to audit.

HPSS requirements

Principles and criteria (P&Cs) (CPCCs)

V1.2

English | Last updated: 23/10/2023

Principles and criteria are a complete list of the requirements for a given standard or add-on. The foundational requirements each detail an outcome that must be achieved, and the corresponding ways in which compliance can be demonstrated.

HPSS checklist

Checklists

V1.2

English | Last updated: 23/10/2023

xlsx

Checklists are documents containing standard/add-on principles and criteria which are used during the audit/assessment to check whether compliance is achieved. They may also be used to conduct self-assessments.

HPSS addendum to GR

GLOBALG.A.P. general regulations

V1.2

English | Last updated: 22/08/2023

GLOBALG.A.P. general regulations outline the framework of the certification system, including the role and relationship of the GLOBALG.A.P. Secretariat and certification bodies, and provide context for implementing checklist content.

GLOBALG.A.P. approved CBs

The list of GLOBALG.A.P. approved CBs can be filtered by region, country, scope, and status. Click a CB to find more information and contact details.

If you do not filter your search, or filter only according to region and/or country, your search results will also show CBs that offer certification against benchmarked schemes, but which may not have approval for any GLOBALG.A.P. standards and add-ons.

Capacity building

Need assistance with the certification process? Our capacity-building program offers a range of options for training, consultation, and more!

Upcoming events

22 Apr - 26 Apr

2024

Academy training: IFA v6 for fruit and vegetables in French

Location:

Online

Event type:

Academy course

Event format:

Virtual

23 Apr

2024

Seafood Expo Global 2024 – Panel discussion

Location:

Barcelona, Spain

Event type:

Trade fair

Event format:

On-site

A brief history of HPSS

In June 2009, the US-based International Fresh Produce Association (IFPA, formerly the United Fresh Food Safety Council) puts forward a plan to drive the harmonization of Good Agricultural Practices (GAP) standards in the fresh produce industry. The collaboration involves a range of value chain stakeholders – such as producers, buyers, government agencies, CBs, and more – and results in the formation of the Produce GAP Harmonization Initiative.

The initiative develops the food safety-focused Combined Harmonized Standard with the goal of “one audit by a credible third party, acceptable to all buyers,” covering preharvest and postharvest operations and applicable to all fresh produce commodities and all sizes of farms. Version 1 of the Combined Harmonized Standard is published in 2011.

To answer the demand from stakeholders for a food safety-only standard with GFSI recognition, the GLOBALG.A.P. Secretariat licenses the Combined Harmonized Standard, adds the necessary GFSI benchmarking requirements and additional traceability criteria, and uses an amended version of the GLOBALG.A.P. general regulations to enable CBs to seamlessly offer both standards.

HPSS v1 is published in June 2014, becoming obligatory in September 2014.

HPSS completes the GFSI benchmarking process for the first time in 2016, achieving recognition for the fruit and vegetables scope. It is the first GFSI-recognized standard from the industry-wide harmonization initiative for the North American market.

By the end of 2018, there are 67 producers under HPSS certification across the United States, Mexico, and Ecuador. The standard revision process begins for v1.1.

HPSS v1.1, with updated CPCCs and addendum to the GLOBALG.A.P. general regulations, is published in January 2019, becoming obligatory in April 2019. It is subsequently updated to v1.1-2 in September 2019, becoming obligatory in December 2019. By the end of the year, there are 125 producers under HPSS certification in four countries.

HPSS v1.2 is published in August 2020, becoming obligatory in November 2020 and replacing v1.1-2. By the end of 2020, there are 179 producers under HPSS certification. The GLOBALG.A.P. Secretariat reapplies for GFSI recognition, and consultation begins in February 2021.

In May 2021, HPSS achieves renewed GFSI recognition, having been successfully benchmarked against GFSI’s Benchmarking Requirements Version 2020.1.

By the end of 2022, there are 197 producers under HPSS certification in five countries. The revision process for v1.3 begins in May 2023, with an estimated publication date for the new version of the standard in mid-2024.

FAQ

Questions about FSMA?

See our dedicated FAQ for information on FSMA rules for the fresh produce industry, including producers, postharvest facilities, importers, and certification bodies.

Contact us

For technical/interpretation questions, please contact us at standard_support@globalgap.org.

For questions about the audit process or GLOBALG.A.P. IT systems, please contact us at customer_support@globalgap.org.