Core solution

Integrated Farm Assurance for aquaculture

Integrated Farm Assurance (IFA) for aquaculture is a global standard for responsible farming practices at all stages of primary production. It is built on a holistic approach that covers the key topics of food safety, the environment (including biodiversity), animal welfare, workers’ well-being, production processes, and traceability.

GLOBALG.A.P.’s flagship standard

What is Integrated Farm Assurance for aquaculture?

Developed with participation from a wide range of sector stakeholders, Integrated Farm Assurance (IFA) for aquaculture provides producers with clarity on international requirements for responsible farming and facilitates a long-term holistic approach to primary production operations. It covers a wide range of finfish, crustacean, mollusc, and seaweed (macroalgae) species. The standard has consistently achieved Global Food Safety Initiative (GFSI) and Global Seafood Sustainability Initiative (GSSI) recognition, and is aligned with the four pillars of the Food and Agriculture Organization (FAO) Technical Guidelines on Aquaculture Certification as well as the World Organization for Animal Health Aquatic Animal Health Code. Operational for over 20 years, IFA is tried, tested, and trusted around the world – with over 2.5 million metric tons of farmed seafood produced in IFA-certified production processes annually.

IFA for aquaculture at a glance

Addresses all stages

of production, from feed and hatchery to harvesting and transportation

Certification options

for a variety of sizes and types of aquaculture farms, including producer groups

Production processes

for over 35 species of finfish, crustaceans, and molluscs currently under certification

Easily combinable

with a range of targeted add-ons and supply chain solutions for flexible assurance customization

Relevant for all

major types of production systems, from net enclosures to closed recirculation systems

Implemented worldwide

with a global network of approved CBs and Registered Trainers

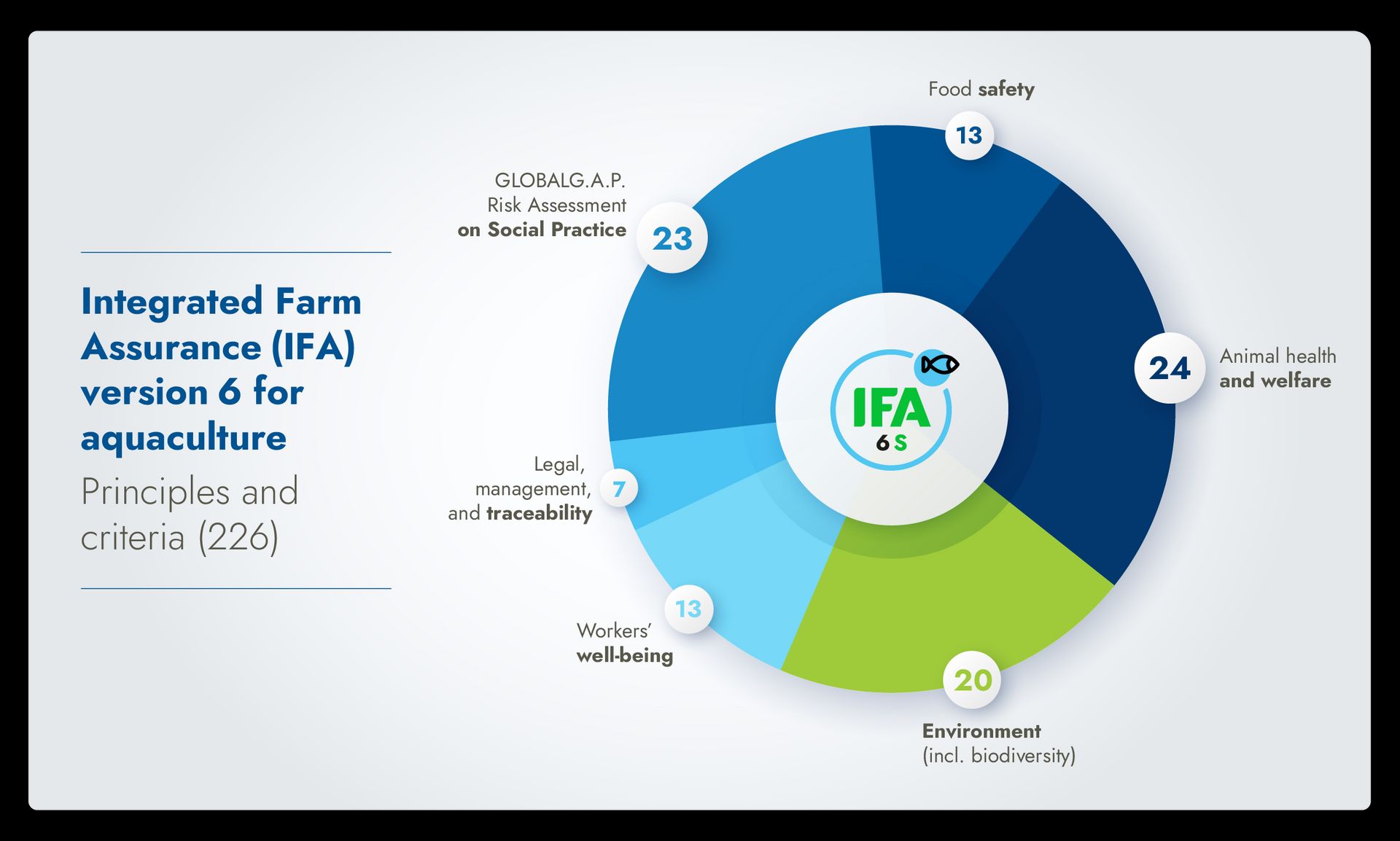

Which topics does IFA for aquaculture address?

IFA for aquaculture covers all stages of production, from hatchery to postharvest activities. The standard has been developed together with sector experts in the technical committees and focus groups and underwent extensive public consultation as part of our process for standard setting

This ensures that IFA remains robust, realistic, and cost-efficient for producers while meeting the evolving demands of buyers.

Core topics in IFA v6 for aquaculture include:

Food safety

Farmed aquatic species welfare, management, and husbandry

Workers’ well-being: occupational health, safety, and welfare

Environment and biodiversity management

Mass balance and traceability

Feed management

Sampling and testing of farmed aquatic species

Harvesting and postharvesting operations

Hygiene

Site management

Discover more about how IFA helps you address challenges in the aquaculture sector.

Who should use IFA for aquaculture?

IFA for aquaculture is available for the entire spectrum of producers worldwide, addressing a range of production systems, including:

Net enclosures

Flow-through systems

Closed recirculation systems

Pond farming

Mollusc/Seaweed (macroalgae)

It offers certification options for both individual producers (single site and multisite producers) and producer groups. Producers can get certification in any country where a GLOBALG.A.P. approved certification body (CB) conducts audits.

IFA for aquaculture can be implemented for the production processes for any aquatic species listed in the GLOBALG.A.P. product list. Certification is linked to the scientific name to support traceability across the supply chain.

How does IFA for aquaculture work?

Compliance with the standard requirements is audited annually by an accredited and independent third-party CB.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a certificate valid for one year.

The GLOBALG.A.P. Risk Assessment on Social Practice (GRASP) is a mandatory add-on to IFA for aquaculture. Producers must also source feed from manufacturers with production processes certified to the Compound Feed Manufacturing (CFM) standard or a recognized feed safety scheme.

IFA v6 checklists are generated digitally and are tailored to the producer’s specific production practices, eliminating any not applicable requirements. Our smarter, streamlined, and outcome-oriented approach also provides flexibility to producers in demonstrating compliance.

The standard is composed of principles and criteria (P&Cs). P&Cs are graded in three levels: Major Must, Minor Must, and Recommendation.

Principles

Fundamentals that set the foundation of a GLOBALG.A.P. requirement

Written in statement form

Describing the outcome to achieve

Criteria

Methods that producers can use to demonstrate a principle to be true

Different ways to demonstrate compliance, e.g., data, record of procedure

Evidence required for demonstrating that the outcome is achieved

Read more about the audit process and standard requirements.

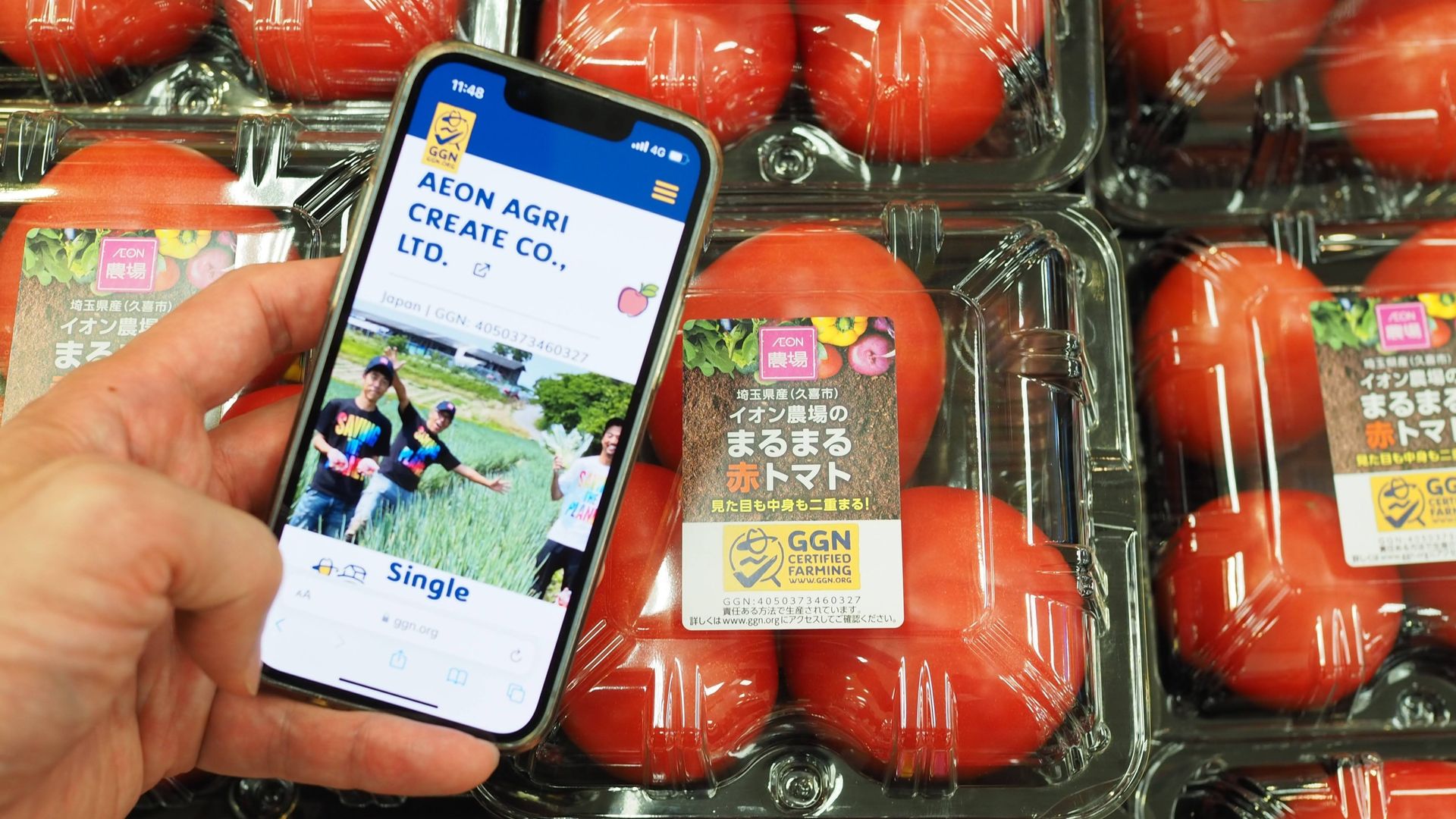

How is certification status verified?

Every producer registered in the GLOBALG.A.P. certification system is assigned a 13-digit GLOBALG.A.P. identification number (e.g., a GLOBALG.A.P. Number (GGN)). This number allows real-time verification of certification status in the GLOBALG.A.P. IT systems, upholding our rigorous transparency requirements throughout the supply chain.

As aquaculture producers with IFA-certified production processes must source feed from

compound feed manufacturers under CFM certification, the GGN of the compound feed

manufacturer is also displayed in the GLOBALG.A.P. IT systems.

Producers can control data access and privacy rights for audit reports, and the reports are not shared publicly or with third parties. This process is handled via your chosen CB.

What are the two editions of IFA v6?

IFA v6 for aquaculture is available in two parallel and equally valid editions:

IFA v6 Smart, which fully embodies the GLOBALG.A.P. philosophy and is appropriate for

the majority of producersIFA v6 GFS, designed for producers who require certification with recognition from GFSI

This decision stems from the extensive public consultation conducted during the standard revision.

Many industry experts requested a more flexible and outcome-oriented IFA, but it was not possible to completely reconcile their preferences with GFSI requirements. To provide solutions for both use cases and to ensure that IFA certification continues to be applicable for the mass market, two editions were developed: IFA v6 Smart and IFA v6 GFS.

There are no differences in the P&Cs of the two editions for aquaculture. There are some differences in the GLOBALG.A.P. general regulations, such as rules for group certification and

unannounced CB audits. Customer requirements usually determine the edition that a producer will implement.

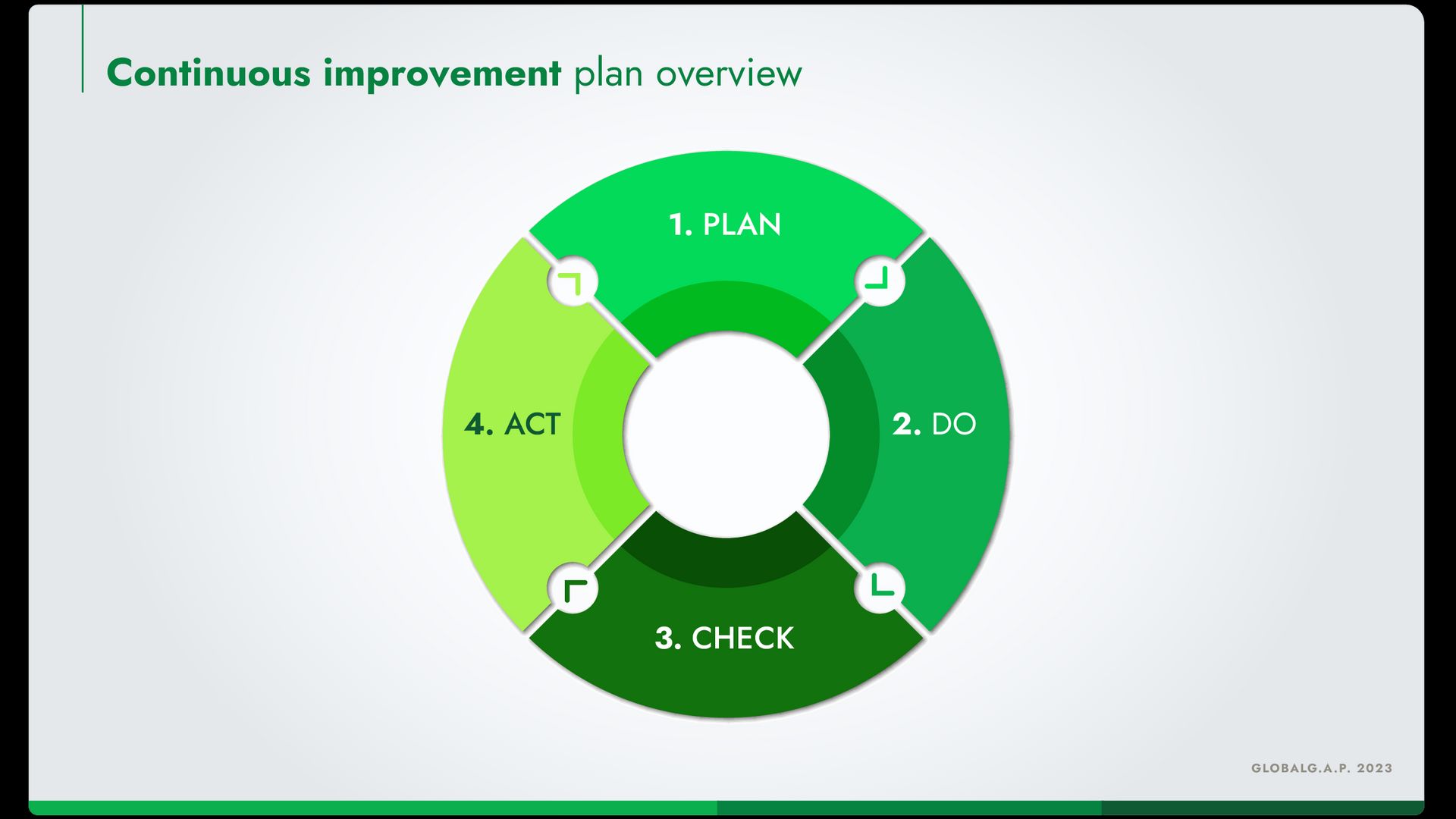

What is the continuous improvement plan?

IFA v6 for aquaculture introduces the need for a continuous improvement plan at farm level. This approach encourages measurable target setting that helps producers to improve the efficiency of their operations and achieve recognition for efforts to strengthen on-farm sustainability.

Plan: After analyzing current practices, data identifies areas that can be improved, and the producer sets measurable goals for improvement.

Do: Targeted measures are implemented in farming practices.

Check: Implementation is checked and progress reviewed at the annual CB audit.

Act: The continuous improvement plan is revised based on progress and impact.

Latest news

25 June 2024

GLOBALG.A.P. SUMMIT 2024: Latest updates

Anticipation for the GLOBALG.A.P. SUMMIT 2024 (10–12 September in Warsaw, Poland) is building and we're delighted to share the latest updates with you: Exclusive warm-up webinar, latest agenda announcements, and deadline for Early Bird tickets

20 June 2024

2023 Integrity Report is out now!

Find out about the activities of the GLOBALG.A.P. Integrity Program in our report - published annually.

Technical news

Full technical newsletters are available in the document center, but you can view technical news updates by topic in our technical news libraries.

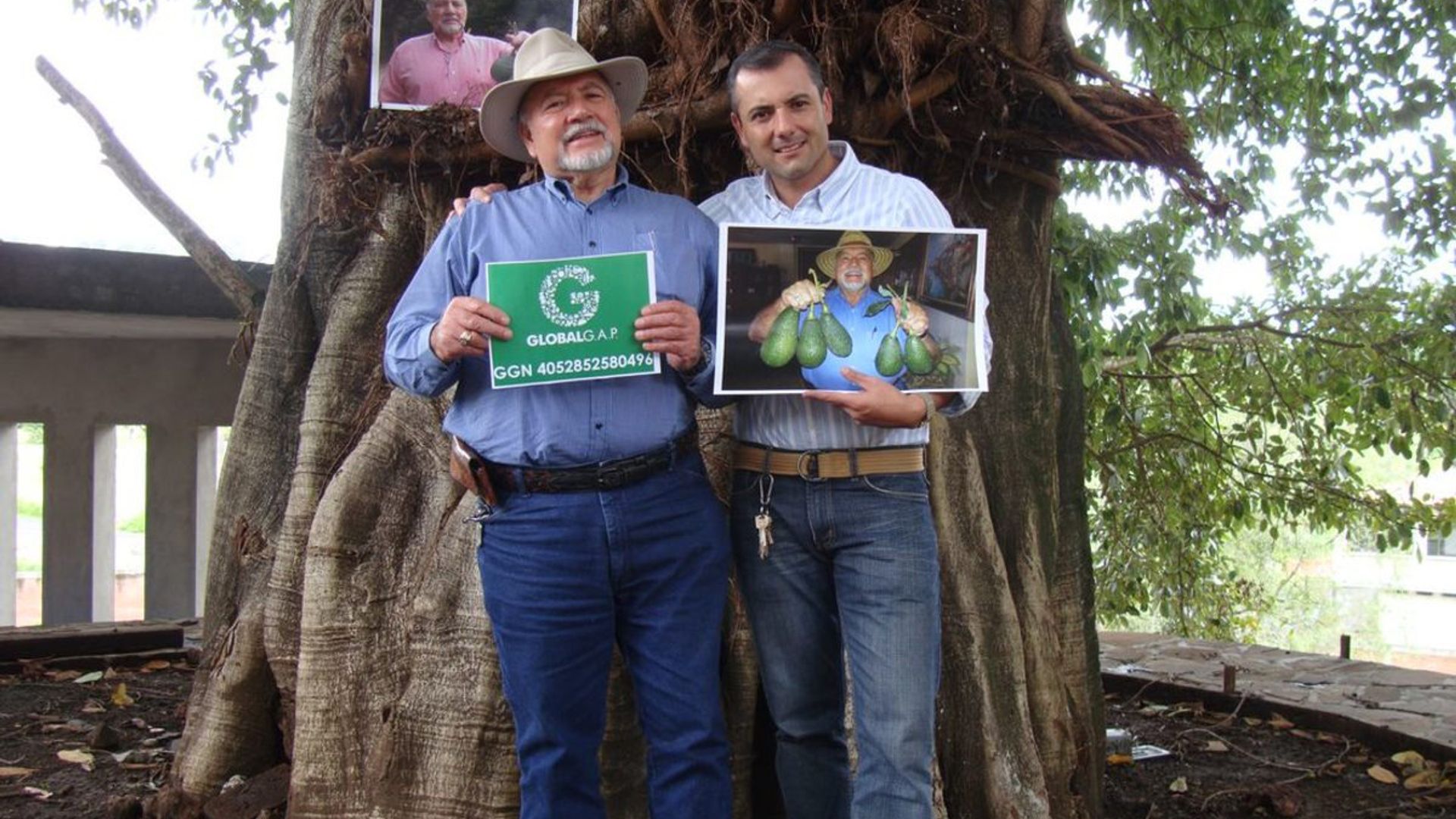

Making responsible farming visible to consumers

IFA certification is one of the requirements for using the GGN label – a consumer label for certified, responsible farming and transparency found on fruit and vegetables, farmed seafood, flowers, and plants. Improve your competitive edge and grow trust in your brand by making responsible farming visible on store shelves!

Demonstrate your commitment to safer and more sustainable farming

Why choose Integrated Farm Assurance for aquaculture?

Integrated Farm Assurance (IFA) is a leading smart farm assurance solution for aquaculture – enabling producers worldwide to assess, demonstrate, and improve their responsible farming practices. IFA v5.4-1 GFS is the only aquaculture standard recognized by the Global Food Safety Initiative (GFSI) at primary production level and the only standard recognized by the Global Sustainable Seafood Initiative (GSSI) for all species of finfish, crustaceans, molluscs, and seaweed (macroalgae). IFA certification is requested by retailers across the globe and provides a practical path for producers to implement best practices at farm level that contribute to the long-term viability of the sector, the welfare of farming communities, and the sustainability of surrounding ecosystems.

Which industry challenges does IFA for aquaculture address?

The vital role of aquaculture for food security has received heightened recognition from

the Food and Agriculture Organization (FAO) in the context of climate change and a

growing global population.Aquaculture is now the fastest growing food sector worldwide, and standards are needed

to ensure that market demand is met with responsible farming practices.Food safety, animal welfare, and environmental sustainability are all under increasing

scrutiny from consumers and supply chain stakeholders.In particular, the rising interaction between the environment and aquaculture due to

growing demand produces risks such as biodiversity loss if not managed effectively.Workers’ health, safety, and welfare are also essential for socially responsible production,

with key social and economic issues such as labor exploitation and human rights in the

spotlight due to new legislation in global supply chains.The certification of production processes for aquaculture and animal feed can help reduce

traceability barriers, supporting both targeted improvements and transparency for buyers.

Follow our five steps to certification to get started today.

IFA for aquaculture in numbers (as of 31/12/2022)

32

aquatic species under certification

28

countries with certified production processes

2.5 million

metric tons of certified production

What are the benefits for producers?

Improve farm management and the efficiency of farm operations.

Adopt a holistic approach that covers food safety, animal health and welfare, environment and biodiversity, workers’ well-being, production processes, legal compliance, and traceability.

Get recognition for your efforts to implement responsible farming practices, including social responsibility through the inclusion of the GLOBALG.A.P. Risk Assessment on Social Practice (GRASP).

Achieve compliance with a globally recognized standard that fulfills international supply chain requirements.

Enjoy a flexible approach to farm assurance through the easy combination of add-ons and the opportunity to join the consumer-facing GGN label initiative.

Choose from an extensive worldwide network of accredited, GLOBALG.A.P. approved certification bodies (CBs).

Access certification options for both individual producers and producer groups.

Apply our farm assurance solutions on a wide range of farm types and sizes, covering all major types of production systems and numerous species of finfish, crustaceans, molluscs, and seaweed (macroalgae).

Optimize your production processes through a continuous improvement plan.

What are the benefits for supply chain stakeholders?

Secure traceability and reliability throughout the supply chain – mitigating reputational risks through transparency of all stages of primary production.

Promote the implementation of key sustainability topics through the holistic approach that features rigorous criteria on food safety, animal health and welfare, environment and biodiversity, workers’ well-being, production processes, legal compliance, and traceability.

Request one standard covering a wide range of species of finfish, crustaceans, molluscs, and seaweed (macroalgae) – aligned with the FAO Technical Guidelines on Aquaculture Certification and supporting the United Nations Sustainable Development Goals.

Access a flexible farm assurance portfolio that provides all the coverage you need through one certification system.

Support sector-driven smart farm assurance solutions and demonstrate your commitment to responsible farming practices.

Contribute to social responsibility through the mandatory inclusion of GRASP, as well as environmental sustainability through the requirement to source from certified compound feed production processes.

Source from a growing pool of producers with certified production processes globally, with easy certification verification in the GLOBALG.A.P. IT systems.

Unlock opportunities to participate in the GGN label initiative.

With GLOBALG.A.P. IFA certification we improved our skills on health and safety and environmental topics. Our employees are much more conscious about fish welfare and biodiversity.

Engin Mola

Quality System Manager at Kilic Seafood Co. | Türkiye

Maintaining trust in GLOBALG.A.P. certification

The GLOBALG.A.P. Integrity Program was founded in 2008 as the first of its kind in food certification. Designed to ensure the consistent delivery and implementation of GLOBALG.A.P. standards and add-ons worldwide, the program monitors and assesses all aspects of the third-party certification process.

Which solutions can be combined with IFA for aquaculture?

We offer a range of standards and add-ons targeted to specific aspects of production and the supply chain. They can each be audited or assessed in combination with IFA, extending the certification scope and offering buyers specific assurance tailored to their preferences.

Learn more about GLOBALG.A.P. smart farm assurance solutions.

You may also be interested in...

Compound Feed Manufacturing

CFM is a global feed mill standard for commercial compound feed production processes.

Impact-Driven Approach to Sustainability add-on

The IDA add-on promotes more sustainable farming practices through the collection and analysis of input consumption data and sustainability metrics.

NON-GM/“Ohne Gentechnik” Add-on

The NON-GM/“Ohne Gentechnik” Add-on enables aquaculture, compound feed, and supply chain stakeholders to demonstrate that their products are free from GMOs.

Ready to get started?

Use our Smart Checklist Builder to easily understand which GLOBALG.A.P. smart farm assurance solutions are recommended for your production practices and generate a personalized checklist for your self-assessment.

Your guide to implementation

How to prepare for an Integrated Farm Assurance audit

Learn more about the key documents and fee structure of Integrated Farm Assurance (IFA) for aquaculture. Follow our five steps to certification for an overview of the certification process, and find a GLOBALG.A.P. approved certification body (CB) in your area to get started.

Implementation and CB audit process

How does the CB audit process work?

IFA compliance is audited annually by accredited and independent third-party CBs.

Producers can choose from any GLOBALG.A.P. approved CB active in the relevant country.

A successful CB audit results in a certificate valid for one year.

The CB is responsible for uploading the audit report and maintaining the accuracy of producer data in the GLOBALG.A.P. IT systems.

Producers will be audited annually by a CB as part of the renewal process.

Which documents are required?

GLOBALG.A.P. general regulations: Rules that define how the certification process works, from the scope of the standard to the audit requirements. Scope-specific regulations also outline the certification process for each IFA scope (e.g., rules for aquaculture).

Principles and criteria (P&Cs): Principles are the fundamental requirements for each standard. They describe the outcomes to achieve and are accompanied by corresponding criteria that detail the ways in which a producer can demonstrate compliance.

Checklist: The full list of P&Cs as used by CB auditors, enabling producers to conduct a self-assessment in preparation for the CB audit.

Which versions of IFA are currently valid?

IFA is currently in transition from v5 to v6. There are currently two valid versions available for certification:

IFA v6 was published in April 2022 in two editions: IFA v6 Smart and IFA v6 GFS.

IFA v6 Smart became obligatory on 1 January 2024, replacing v5.2.

IFA v6 GFS becomes obligatory and replaces v5.4-1-GFS after Global Food Safety Initiative (GFSI) recognition is achieved (estimated for Q3 of 2024 – a transition period will be announced in due course).

IFA v5.4-1-GFS was published in October 2021 and is recommended for producers who require certification with GFSI recognition. It will continue to be available for audit until v6 GFS achieves GFSI recognition. Certificates achieved before v6 GFS becomes obligatory will be valid and GFSI-recognized for their full cycle.

The FAQ contains further information on documents, certification renewal, and more.

Transitioning from IFA v5 to IFA v6?

Our transition tools can help you cross-reference the requirements and support your transition to the newest version.

What are the IFA standard requirements?

P&Cs are graded in three levels: Major Must, Minor Must, and Recommendation.

To achieve certification, producers must comply with 100% of the Major Musts and at least 95% of the Minor Musts.

Corrective actions must be proposed for all non-compliances and submitted to the CB within the specified period.

Non-compliances must then be verified as corrected and compliant by the CB before a certificate can be issued.

What are the requirements for aquaculture inputs?

Aquaculture producers with IFA-certified production processes must source compound feed from mills that are certified to one of the following:

A standard that has been successfully benchmarked against the CFM standard

A feed safety scheme accredited according to ISO/IEC 17065 or ISO/IEC 17021

Based on ISO/IEC accreditation, certification to the following feed safety schemes is considered sufficient to comply with the requirements. However, they are not officially benchmarked or recognized as equivalent to the CFM standard:

FSSC Feed (including PAS 222)

SQF Code for Feed

Universal Feed Assurance Scheme (UFAS)

Visit the recognized feed safety schemes section of the CFM web page for more information.

How much does IFA certification for aquaculture cost?

Each farm is unique, and the total costs of certification depend on a combination of factors such as farm size, number of sites, location, necessary preparation measures (such as establishing new procedures), and more. IFA contains three cost elements:

Implementation costs: Incurred by the producer to prepare for the CB audit

CB service fees: Determined and invoiced by the CB to cover audit time and travel costs

GLOBALG.A.P. registration and certificate license fees :Calculated based certification option and on metric tons of aquaculture products produced in certified production processes and invoiced by the CB

The GLOBALG.A.P. fee table contains full information on the fee structure for each standard and add-on.

Five steps to certification

You will need the GLOBALG.A.P. general regulations, the IFA P&Cs for aquaculture, and the

checklist. All of the required documents are available online, for free, and in multiple

languages. They are linked below and can also be found in the GLOBALG.A.P. document center.

Use the documents to guide the implementation of the standard requirements, and then

conduct a self-assessment using the checklist. Our worldwide network of Registered Trainers

can also provide assistance during audit preparations.

Search the list of GLOBALG.A.P. approved CBs by region, country, scope, and status. Contact the CB of your choice and request an audit. Note that the GLOBALG.A.P. fee table does not cover CB service fees such as audit time or travel costs to your site.

The CB will conduct the audit and upload the results to Audit Online Hub. Any non-compliances which are detected during the CB audit must be corrected within the specified period and verified by the CB before a certificate can be issued.

Once all requirements are met and verified by the CB, they will issue your IFA certificate. Your

certification status is then publicly visible in the GLOBALG.A.P. IT systems for transparency in

the market.

Key documents

The three most relevant documents are linked below. Click ‘view more’ to see further related documents. Remember to always check with your CB that you have all necessary documents prior to audit.

IFA v6 Smart/GFS for aquaculture

Principles and criteria (P&Cs) (CPCCs)

V6

English | Last updated: 22/05/2024

Principles and criteria are a complete list of the requirements for a given standard or add-on. The foundational requirements each detail an outcome that must be achieved, and the corresponding ways in which compliance can be demonstrated.

Rules for aquaculture scope

GLOBALG.A.P. general regulations

V6

English | Last updated: 22/05/2024

GLOBALG.A.P. general regulations outline the framework of the certification system, including the role and relationship of the GLOBALG.A.P. Secretariat and certification bodies, and provide context for implementing checklist content.

Transition tool IFA v5.4-1 GFS IFA v5.2 to IFA v6 Smart/GFS for aquaculture

Guidelines and supporting documents

English | Last updated: 13/05/2024

xlsx

Guidelines and supporting documents are developed by the GLOBALG.A.P. Secretariat to help producers understand the terminology, legal requirements, and farm-level implementation of GLOBALG.A.P. standards and add-ons.

GLOBALG.A.P. approved CBs

The list of GLOBALG.A.P. approved CBs can be filtered by region, country, scope, and status. Click a CB to find more information and contact details.

If you do not filter your search, or filter only according to region and/or country, your search results will also show CBs that offer certification against benchmarked schemes, but which may not have approval for any GLOBALG.A.P. standards and add-ons.

CERTIPAQ

Country

FranceStatus

ApprovedRating

4.19CTR Uluslararası Belgelendirme ve Denetim Ltd. Şti.

Country

TurkeyStatus

ApprovedRating

PendingBureau Veritas Certification Denmark A/S

Country

DenmarkStatus

ApprovedRating

3.88UK Food Certification Ltd

Country

United KingdomStatus

ApprovedRating

Pending1st Solution Certification USA, Inc.

Country

United States of AmericaStatus

ApprovedRating

PendingAGROCOLOR S.L.

Country

SpainStatus

ApprovedRating

3.8Eurofins Assurance Vietnam Limited Liability Company

Country

Viet NamStatus

ApprovedRating

3.96SGS Italia S.p.A.

Country

ItalyStatus

ApprovedRating

3.51Japan Organic & Natural Foods Association

Country

JapanStatus

ApprovedRating

4.044PLUS INGENIEROS Y ARQUITECTOS S.L

Country

SpainStatus

ApprovedRating

4.45ABCERT AG

Country

GermanyStatus

ApprovedRating

3.99ACERTA Certificación, S.L.

Country

SpainStatus

ApprovedRating

4.14Acoura Marine Ltd. trading as LRQA

Country

United KingdomStatus

ApprovedRating

3.98Compound Feed Manufacturing Standard v.2 accreditation is limited to aquaculture feed

AFRICERT LTD

Country

KenyaStatus

ApprovedRating

3.78Yellow Card sanction according to GR v6, Rules for Certification Bodies, 11.3.

AGFO Teknik Kontrol ve Belgelendirme Hizmetleri Ltd. Şti.

Country

TurkeyStatus

ApprovedRating

3.85Capacity building

Need assistance with the certification process? Our capacity-building program offers a range of options for training, consultation, and more!

Upcoming events

15 Aug

2024

IFA supports people: Fostering ethical labor practices for a sustainable future

Location:

Online

Event type:

Webinar

Event format:

Virtual

26 Aug - 30 Aug

2024

Academy training: IFA v6 for fruit and vegetables in French

Location:

Online

Event type:

Academy course

Event format:

Virtual

A brief history of IFA for aquaculture

In October 2004, EUREPGAP launches its first aquaculture standard for salmonids to promote the responsible farming of seafood. In May 2005, the GLOBALG.A.P. Chain of Custody (CoC) standard is launched to safeguard products from certified production processes up to the point of sale, as well as the development of a Compound Feed Manufacturer Reference Module.

In 2008, the GLOBALG.A.P. shrimp standard is launched in collaboration with the International Union for Conservation of Nature (IUCN) for the criteria for high conservation value areas, and with Oxfam-Novib for the social criteria for shrimp farming.

By 2009, standards for tilapia and pangasius are launched. After a four-year revision process, the harmonization of criteria takes place to cover finfish, crustaceans, and molluscs in a single standard. IFA v4 goes through consultation and is launched in March 2011, and by the end of 2012, the number of certificates has risen to 162 in 21 countries.

Annual production from certified production processes reaches 1.5 million metric tons, with the largest number of producers under certification active in Vietnam, Norway, and Turkey.

Certified production processes in 2014 cover 23 aquatic species, with more than 250 certificate holders globally. Annual production from certified production processes passes 2 million metric tons. Public consultation for IFA v5 takes place from January 2014 to July 2015, with the standard becoming obligatory in 2016.

The inclusion of the GLOBALG.A.P. Risk Assessment on Social Practice (GRASP) becomes mandatory for IFA for aquaculture, strengthening social responsibility. Key updates in v5 also include more rigorous criteria on environmental sustainability, animal welfare, and feed. By 2018, there are 338 certificate holders in 33 countries.

The technical committees agree on the structure and workflow for the IFA v5.2 to v6 revision process. The draft is put to a first public consultation from May to June 2020, a second from November 2020 to January 2021, and a third from May to July 2021.

Following a fourth and final public consultation from August to September 2021, the standard is approved by the technical committees and officially adopted by the GLOBALG.A.P. Advisory Board in October. The interim final version of IFA v6 for aquaculture is published in April 2022, and the final version follows in September.

IFA-certified production processes are now producing over 2.5 million metric tons of aquaculture products for the global market annually.

IFA v6 Smart for aquaculture becomes obligatory on 1 January 2024. The GFS edition will become obligatory following a transition period after achieving GFSI recognition.

FAQ

Contact us

For technical/interpretation questions, please contact us at standard_support@globalgap.org.

For questions about the audit process or GLOBALG.A.P. IT systems, please contact us at customer_support@globalgap.org.